More Yellow Fever Black Magic (Rislone Mustang) Episodes

Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

American Powertrain Systems

MAGNUM XL 6-Speed Kit for 2005-2016 Mustang V8, Direct replacement, includes SFI bell, cross member, mount, shifter assembly, shifter handle and knob, 26-spline input, quick launch 2.97, 2.10, 1.46, 1:1, .80, .63

EXEDY GLOBALPARTS CORPORATION

Stage 2 clutch kit part number: 07953CSC

EXEDY GLOBALPARTS CORPORATION

Lightweight racing flywheel part number: EF502A

LATE MODEL RESTORATION

2015-17 Ford Mustang Ford Performance Brembo 6 Piston Brake Kit - S550 by Ford Performance

LATE MODEL RESTORATION

2015-17 Ford Mustang Ford Performance Handling Pack Coupe - S550

LATE MODEL RESTORATION

2015-17 Ford Mustang SVE Series 3 Wheel & Tire Kit - 20x8.5/10 Gloss Black - Nitto Invo - S550

Precision Shaft Technologies (PSTDS)

Custom Built Driveshaft

The Industrial Depot

INDUSTRIAL DEPOT - FASTENERS, HARDWARE, AND SHOP SUPPLIES

Episode Transcript

(MIKE)>> WELCOME TO ENGINE POWER. TODAY WE HAVE A LOT OF WORK TO DO TO FINISH THE RISLONE MUSTANG SWEEPSTAKES CAR. NOW IT'S A 2016 MUSTANG GT THAT'S BEING GIVEN AWAY TO ONE OF YOU LUCKY VIEWERS. SO FAR WE'VE INSTALLED A FORD PERFORMANCE TRACK HANDLING PACK, MASSIVE 15 INCH FRONT BRAKES, SVE WHEELS, AND NITTO TIRES. TODAY STARTS THE FINAL PHASE OF THE BUILD.

(PAT)>> AND IT'S GONNA MAKE A STATEMENT. WE'RE INSTALLING ONE OF PRO CHARGER'S STAGE TWO KITS ON THE CAR THAT UTILIZES THEIR NEW PONEX SUPERCHARGER. NOW IT'LL MAKE 10 POUNDS OF BOOST WITH THE SUPPLIED PULLEYS, AND AT 10 PSI THIS FIVE LITER WILL MAKE OVER 700 HORSEPOWER, WHICH IS PRETTY IMPRESSIVE, AND MIKE HAS ALREADY GOTTEN STARTED ON THE INSTALL. SO WHAT DO YOU HAVE ACCOMPLISHED SO FAR?

(MIKE)>> SO FAR I'VE GOT THE AIR BOX OUT OF THE WAY, THE SOUND TUBE THAT GOES TO THE FIREWALL, COOLANT'S DRAINED, THE FRONT FASCIA'S READY TO COME OFF, AND I WENT AHEAD AND PUT THE NEW THERMOSTAT HOUSING ON.

(PAT)>> FANTASTICAL, LET'S GET THE HOOD OFF FOR A LITTLE MORE ELBOW ROOM AND WE'LL GO FROM THERE.

(MIKE)>> FOUR HANDS ARE BETTER THAN TWO.

(PAT)>> I LIKE IT.

(MIKE)>> BEING CAREFUL WHEN REMOVING THE FASCIA IS A MUST. IT'S A PAINTED BODY PANEL. YOU DON'T WANT TO SCRATCH OR DAMAGE IT IN ANY WAY. BODY SHOP REPAIRS ARE EXPENSIVE.

(PAT)>> JEEZ LOUISE!

(MIKE)>> NEXT TO COME OFF IS THE COOLANT RESERVOIR. A FEW HOSES NEED TO BE REMOVED, AS WELL AS TWO 10 MILLIMETER FASTENERS. IT'S NOT BEING REUSED. INCREASING THE HORSEPOWER LIKE WE'RE GOING TO DO WITH THE SUPERCHARGER MEANS WE HAVE TO ADDRESS THE FUEL SYSTEM. NOW PRO CHARGER INCLUDES BRAND NEW 95 POUND AN HOUR INJECTORS IN THE SYSTEM. NOW THESE THINGS ARE FLOW TESTED AND MATCHED UP IN GROUPS OF EIGHT FOR EVEN DISTRIBUTION ACROSS BOTH BANKS. WE HAVE TO GET THE OLD ONES OUT TO GET THESE IN. THE BRACKETS AND FOAM INSULATORS THAT ARE OVER THE FUEL RAILS COME OFF FIRST. NOW DISCONNECT THE ELECTRICAL CONNECTORS FROM THE INJECTORS. WITH A RAG UNDER THE SUPPLY LINE, DISCONNECT IT AND LET THE RAG SOAK UP ANY FUEL THAT COMES OUT. WITH THE FOUR BOLTS SECURING THE RAIL REMOVED, LIFT IT OFF THE ENGINE.

(PAT)>> HERE'S A QUICK TIP. WHEN YOU'RE CHANGING OUT INJECTORS, LEAVE THEM IN THE RAIL AND DO IT AWAY FROM THE VEHICLE. REASON BEING YOU COULD INADVERTENTLY FILL AN OPEN HOLE WITH GASOLINE BECAUSE WHEN YOU PULL THE INJECTOR OUT GAS FROM THE RAIL CAN RUN DOWN IN A CYLINDER, AND IF THAT HAPPENS AT BDC ON A COMPRESSION STROKE, WHEN YOU PUT IT BACK TOGETHER AND START THE VEHICLE YOU CAN POTENTIALLY BEND A CONNECTING ROD BY HYDROLOCKING IT, AND THAT WILL RUIN YOUR DAY. SWAPPING THE INJECTORS IS EASY. MAKE SURE THE ORINGS ARE LUBED, AND THEY'LL GO RIGHT IN. THE RETAINING CLIPS PUSH ON FROM THE BACK SIDE. NOW THE FUEL RAIL ASSEMBLY IS REPOSITIONED MAKING SURE THE INJECTOR SEATS ALL THE WAY DOWN IN THE MANIFOLD'S INJECTOR BOSSES. FINALLY ALL THE FACTORY PIECES CAN GO BACK ON THE SAME WAY THEY WERE REMOVED.

(MIKE)>> UP FRONT THE PLASTIC RADIATOR SHROUDS CAN BE REMOVED. THERE'S A RIGHT AND LEFT SIDE. PRO CHARGER'S CRANK PULLEY HAS AN EIGHT RIB BELT GROOVE. NOW THIS ATTACHES TO THE FACTORY PULLEY IN TWO DIFFERENT WAYS. THE FIRST IS A SUPPLIED BALANCER BOLT THAT COMES IN THE PRO CHARGER KIT. THE SECOND ARE THESE AWESOME LITTLE CAM LOCKS THAT WEDGE THEMSELVES BETWEEN THE FACTORY PULLEY. THAT KEEPS THE PRO CHARGER ONE FROM ROTATING DUE TO THE FORCE OF THE SUPERCHARGER BELT. THEY'RE ATTACHED TO THE BACK SIDE OF THE PULLEY WITH SUPPLIED HARDWARE. MAKE SURE THE CAM LOCKS ARE POSITIONED AWAY FROM EACH OTHER BECAUSE EACH PAIR STRADDLES ONE OF THE STOCK BALANCER'S WEBS.

(PAT)>> THE PRO CHARGER PIECE IS NOW PLACED IN THE CENTER OF THE STOCK BALANCER. THE NEW BALANCER BOLT IS HAND TIGHTENED, AND THE NEW PULLEY IS ROTATED COUNTER CLOCKWISE UNTIL THE CAM LOCKS STOP IT FROM ROTATING. LIGHTLY TIGHTEN THE BALANCER BOLT, TORQUE THE CAM LOCK BOLTS TO 28 POUND FEET, AND FINALLY TIGHTEN THE BALANCER BOLT TO 35 POUND FEET PLUS 90 DEGREES.

(MIKE)>> NEXT THE SUBBRACKET IS BOLTED TO THE TIMING COVER USING SUPPLIED BOLTS. THE RADIATOR BRACKETS ARE REMOVED NEXT SO WE CAN SLIP THESE RUBBER ISOLATORS OVER THE RADIATOR MOUNTING POST. NOW THE NEW RADIATOR BRACKETS ARE INSTALLED. THEY MOVE THE RADIATOR AWAY FROM THE ENGINE FOR SUPERCHARGER CLEARANCE. A HEX STANDOFF IS THREADED ONTO THE ALTERNATOR STUD, AND THE SUPERCHARGER BRACKET ASSEMBLY IS PUT IN PLACE. THIS BRACKET IS NO JOKE. IT'S SUPER SOLID AND ENGINEERED FOR STRENGTH AND DURABILITY. IT IS POSITIONED IN FRONT OF THE DRIVER'S SIDE CYLINDER HEAD AND ATTACHES WITH FOUR FASTENERS FOR A RIGID, ROCK SOLID MOUNT.

(PAT)>> NOW IT'S TIME TO PREP THE SUPERCHARGER. THIS IS THEIR NEW PONEX, WHICH IS AN IMPROVED DESIGN OVER ITS PREDECESSOR, THE PONESCONE. THE IMPELLER AND COMPRESSOR HOUSING HAVE BEEN IMPROVED FOR BETTER EFFICIENCY AND PERFORMANCE, WITH GAINS OF OVER 50 HORSEPOWER. IT'S DESIGNED TO SUPPORT OVER 800 HORSEPOWER AND HAS A 90 MILLIMETER INDUCER. IT'LL FLOW UP TO 1,275 CFM AND HAS A MAXIMUM IMPELLER SPEED OF 65,000 RPM. THIS IS A SELF CONTAINED UNIT, MEANING IT DOES NOT USE THE ENGINE'S OIL TO LUBRICATE THE SUPERCHARGER. SO THERE'S NO TAPPING INTO THE OIL PAN. FOR EASY DRAINING WHEN IT NEEDS LUBE SERVICE A DRAIN LINE IS ATTACHED TO A FITTING AT THE BOTTOM OF THE SUPERCHARGER. NOW WE CAN ADD ONE SIX OUNCE BOTTLE OF SUPERCHARGER OIL. WHEN WE COME BACK THIS BOOST PRODUCER IS MEETING ITS FINAL DESTINATION.

(MIKE)>> WE'RE BACK WITH THE RISLONE MUSTANG BUILD. THE ENGINE BAY IS PREPPED AND READY FOR THE SUPERCHARGER. IT'S ATTACHED USING SIX SOCKET HEAD CAP SCREWS. IT IS NECESSARY TO ACTUATE THE TENSIONER TO GET TO ALL THE FASTENER HOLES. NOW THE BELT IS ROUTED OVER THE CRANK PULLEY AND UP TO THE PRO CHARGER ONE. A SUPPLIED IDLER SHAFT IS INSERTED INTO THE FACTORY IDLER PULLEY, AND THE PRO CHARGER PULLEY IS ATTACHED TO THE SHAFT WITH NEW HARDWARE. TENSIONING THE BELT IS SIMPLE. TURN THE BRASS COLLAR COUNTER CLOCKWISE UNTIL THE FIRST ALIGNMENT MARKS ON THE TENSIONER BODY ALIGN. UNFORTUNATELY THE CAMERA CAN'T SEE IT. NOW TIGHTEN THE PIVOT BOLT. TURN THE BRASS COLLAR CLOCKWISE TO UNLOAD THE TENSION FROM THE JACK SCREW AND FINALLY TIGHTEN THE JACK SCREW MOUNTING BOLT. KEEPING THE INLET AIR TEMPS IN CHECK IN A BOOSTED APPLICATION IS CRITICAL TO MAKING BIG POWER. NOW PRO CHARGER HANDLES THAT IN AWESOME FASHION. THIS IS THEIR STAGE TWO INTERCOOLER THAT USES A FOUR AND A HALF INCH CORE AND HAS A TON OF SURFACE AREA. NOW THIS BOSS IS WHERE THE MASS AIR SENSOR MOUNTS, AND WITH THE BRACKETS ALREADY INSTALLED IT'S READY TO MOUNT TO THE CAR. IT GOES IN FROM THE BOTTOM. BE CAREFUL AND MAKE SURE YOU DON'T GOUGE THE CONDENSER. THE BRACKETS SLIDE OVER THE BUMPER TO FRAME BOLTS, AND ARE SECURED WITH SUPPLIED NUTS. THE MASS AIR SENSOR CAN BE INSTALLED NOW. IT ONLY GOES IN ONE WAY. A HARNESS EXTENSION IS SUPPLIED SINCE THE SENSOR IS MOVED FAR AWAY FROM ITS ORIGINAL LOCATION. HERE'S A LOOK AT THE SCHEMATIC IN THE PRO CHARGER MANUAL OF THE INTERCOOLER AND ITS PIPING. IT ALL FITS JUST HOW LOOKS, REALLY GOOD. THE ROUTING GOES FROM THE OUTLET OF THE SUPERCHARGER DOWN AND AROUND TO THE INLET OF THE INTERCOOLER. NOW THIS INTERCOOLER WILL SUPPORT UP TO 1,200 HORSEPOWER. THE REASON THIS SUPERCHARGER SYSTEM IS SO EFFICIENT IS YOU'LL ONLY SEE AN EIGHT TO 10 DEGREE RISE OVER AMBIENT TEMPERATURE ON 10 POUNDS OF BOOST, AND THAT'S PRETTY IMPRESSIVE. FROM THE OUTLET OF THE INTERCOOLER THE PIPING RUNS BACK UP TO THE THROTTLE BODY. A VACUUM MANIFOLD IS SUPPLIED TO GET A VACUUM SOURCE LOCATION FOR THE PURGE VALVE AND BOOST GAUGE, IF YOU PLAN ON RUNNING ONE IN THE CAR. THIS LINE WENT FROM THE AIR INLET TUBE TO THE VACUUM TREE. IT CAN BE REMOVED AND DISCARDED. NOW THE MANIFOLD IS ATTACHED TO THE TREE USING A THREEEIGHTHS HOSE. A ONE AND A HALF INCH 90 DEGREE HOSE IS PLACED OVER THE INTERCOOLER TUBE'S BUNG, AND A PRO FLOW SURGE VALVE IS ATTACHED TO IT. IT CAN BE MOUNTED IN ANY DIRECTION. PROTECTING IT FROM THE ELEMENTS IS A PRO CHARGER FILTER. A THREESIXTEENTHS VACUUM HOSE IS CONNECTED TO THE VALVE, AND THE OTHER END TO THE VACUUM MANIFOLD. MAKE SURE THIS LINE IS ROUTED WITHOUT TIGHT BENDS AND AWAY FROM SHARP EDGES. A 90 DEGREE ELBOW IS PLACED ON THE SUPERCHARGER INLET. THE OPEN END POINTS INTO THE DRIVER'S SIDE WHEEL WELL. TUBE NUMBER 379 IS NEXT. IT ATTACHES TO THE 90 DEGREE ELBOW. MAKE SURE THE VACUUM "T" IS POINTED TOWARD THE SUPERCHARGER. A CONICAL AIR FILTER IS ATTACHED TO THE OPEN END OF THE PIPE. WE'LL BE RIGHT BACK.

(MIKE)>> WE'RE BACK AND GETTING EXTREMELY CLOSE TO HAVING THE PRO CHARGER STAGE TWO SYSTEM INSTALLED. UP NEXT IS THE PCV SYSTEM. START BY DISCONNECTING THE LINE ON THE BIG PORT BEHIND THE THROTTLE BODY. NOW CAP IT OFF WITH A VACUUM CAP AND CLAMP. REMOVE THE FACTORY PLASTIC LINES THAT CONNECT TO EACH VALVE COVER VENT. I LIKE TO REMOVE THE FITTING FROM THE PLASTIC LINE THAT WENT TO THE VALVE COVER. IT'S ORINGED AND BARBED, SO THE NEW RUBBER HOSE FITS ON IT TIGHT, AND RUN A PIECE OF SUPPLIED FIVEEIGHTHS VACUUM HOSE FROM THE PASSENGER VALVE COVER ACROSS THE FRONT OF THE RADIATOR AND INSTALL A BRASS UNION IN THE END. ANOTHER FIVEEIGHTHS HOSE GOES ON THE DRIVER'S SIDE VALVE COVER VENT AND RUNS DOWN TO THE PLASTIC "T". THE HOSE WITH THE BARB GETS A SHORT EXTENSION AND GOES TO THE OTHER SIDE OF THE "T". AT THE BACK OF THE ENGINE WE CAN REMOVE THE DIAPHRAGM BENT LINE AT THE "Y", AND PULL IT OUT FROM UNDER THE INTAKE MANIFOLD. CUT THE DRIVER'S SIDE PCV HOSE AND SLIP IN THIS "T". NOW CONNECT THE SUPPLIED THREEEIGHTHS RUBBER HOSE TO THE OPEN BARB AND RUN IT TO THE "Y" AT THE BACK OF THE ENGINE. THE FIVEEIGHTHS HOSES WE JUST RAN ARE PART OF THE PCV SYSTEM, OR POSITIVE CRANK CASE VENTILATION. NOW HOW IT WORKS IS AS THE ENGINE RUNS A LITTLE BIT OF PRESSURE BYPASSES THE RINGS AND GETS INTO THE CRANK CASE. NOW AS THAT PRESSURE BUILDS IT NEEDS A PLACE TO GO. SO IT COMES OUT OF THE TOP OF THE VALVE COVERS. FROM THERE IT RUNS OVER TO THE "T" IN THE INTAKE TUBE. NOW IT'S PULLED INTO THE INTAKE MANIFOLD FROM THAT POINT AND BURNED WITH THE AIR/FUEL MIXTURE. PRO CHARGER ALSO ADDRESSES THE FUEL PUMP BY INCLUDING THIS JMS POWER MAX VOLTAGE BOOSTER THAT IS DESIGNED TO PROVIDE UP TO AN 85 PERCENT INCREASE IN FUEL DELIVERY. IT'S TIGHTENED FROM THE BOTTOM. WITH IT MOUNTED, THE GROUND IS RAN TO THE REAR TRUNK PANEL. WITH THE SEAT BOTTOM REMOVED, LOCATE THE FUEL PUMP DRIVER MODULE. CUT THE PURPLE WIRE WITH THE GREEN TRACER IN HALF. NOW THE WHITE WIRE COMING IN FROM THE BOOSTAPUMP GOES TO THE PURPLE WIRE ON THE CONNECTOR SIDE. THE RED WIRE FROM THE BOOSTER PUMP GOES TO THE OTHER END OF THE PURPLE WIRE. NOW WE ONLY HAVE ONE MORE CONNECTION TO MAKE. BACK AT THE ENGINE A PLUG IS REMOVED FROM THE VACUUM MANIFOLD AND REPLACED WITH THIS PRESSURE SWITCH FROM THE VOLTAGE BOOSTER KIT. FINALLY THE NEW COOLANT RESERVOIR CAN BE BOLTED IN, AND THE COOLANT LINES ATTACHED. NEW PLUGS ARE RECOMMENDED. THESE ARE ONE HEAT RANGE COOLER THAN THE FACTORY ONES. THE GAP IS ALSO TIGHTENED UP TO 35 THOUSANDTHS. THE COIL UNPLUG DESIGN MAKES CHANGING THEM A QUICK JOB. I SENT THE FACTORY TUNE FILE TO PRO CHARGER. WITHIN A DAY THEY HAD THE NEW FILE SENT BACK. I'M USING AN NGAUGE TO LOAD IT INTO THE ECM. THIS PROCESS TAKES ABOUT EIGHT MINUTES, BUT IT ONLY TAKES A SECOND TO PUSH THE START BUTTON AND HEAR THIS. [ engine fires up and idles ]

(MIKE)>> LOOKS GOES WITH PERFORMANCE. NO MORE FACTORY HOOD. THIS IS RK SPORT'S RAM AIR FOR '15 AND UP MUSTANGS. IT'S FULLY FUNCTIONAL AND CONSTRUCTED FROM HAND LAID HIGH TEMP CARBON FIBER. IT'S ALSO REINFORCED WITH FIBERGLASS FOR STRUCTURAL RIGIDITY AND HAS A MARINE CLEAR GEL COAT FINISH WITH UV PROTECTION. IT INSTALLS USING THE FACTORY HARDWARE AND FITS EXTREMELY WELL. THE REAR SPOILER IS ALSO HAND LAID CARBON FIBER AND SHARES THE SAME BENEFITS AS THE HOOD. THIS IS A DIRECT REPLACEMENT FOR THE FACTORY WING. FITMENT IS AWESOME.

(MIKE)>> WELCOME BACK! A LOT HAS HAPPENED SINCE YOU'VE BEEN GONE. FIRST UP IS THIS AWESOME FORM FIT CAR COVER FROM COVER CRAFT. IT WAS MADE FOR OUR SWEEPSTAKES AND SPORTS THE RISLONE LOGO. NOW IT'S THE MOST LUXURIOUS INDOOR COVER THEY OFFER. IT LITERALLY FITS LIKE A GLOVE AND THE SUPER SOFT INSIDE PAMPERS FINE PAINT FINISHES. IT HAS A FOUR YEAR WARRANTY AND IS AVAILABLE IN SIX COLORS. CHECK OUT COVER CRAFT DOT COM FOR ALL THEIR PRODUCTS AND COVER STYLES. WE ALSO HAD A SLICK STRIPE PACKAGE PUT ON THE CAR. THESE RACING STRIPES ADDED A TON OF ATTITUDE TO THIS S-550. IT REALLY SETS IT APART FROM ALL THE OTHER STANGS OUT THERE. UNDERNEATH PAT AND I REMOVED THE TRANSMISSION, WHICH LEFT A BIG VOID, BUT THAT WON'T LAST LONG. THE FACTORY TRANSMISSION IS CALLED A GETRAG MT-82. NOW IT HAS A LIMITED PERFORMANCE ENVELOP WHEN IT COMES TO MUSTANGS THAT MAKE A LOT OF HORSEPOWER. NOW THIS TRANNY WILL WORK GREAT FOR DAILY DRIVERS IN CARS WITH SIMPLE BOLT ONS, BUT FOR THE POWER LEVEL WE HAVE IN OUR MUSTANG THIS THING NEEDS TO BE UPGRADED.

(PAT)>> AMERICAN POWERTRAIN NOW OFFERS A BOLT IN TRANSMISSION UPGRADE KIT FOR 2005 AND UP MUSTANGS. IT WILL CONVERT A FIVE SPEED CAR TO A SIX SPEED CAR, AND GIVE YOU A MUCH STRONGER TRANSMISSION FOR THE GETRAG EQUIPPED CARS THAT ARE MAKING BIG POWER. THE KIT IS CENTERED AROUND THEIR NEW MAGNUM XL TRANSMISSION, WHICH IS A CONTINUATION OF THEIR MAGNUM SIX SPEED. THIS ONE IS RATED AT 700 POUND FEET OF TORQUE, AND THEY'VE ELIMINATED THE RUBBERY SHIFT LINKAGE TO A DIRECT THROW SHIFTER. THE KIT COMES WITH AN SFI APPROVED STEEL BELL HOUSING, CROSS MEMBER, TRANS MOUNT, SHIFTER AND BALL, AND A SPEEDOMETER INTERFACE. NOW THE SYSTEM USES STOCK HYDRAULICS BUT YOU WILL HAVE TO SWITCH TO A 26 SPLINE CLUTCH DISC AND GET A CUSTOM ONE PIECE DRIVESHAFT.

(MIKE)>> THE FIRST PART TO GO ON IS THE ENCLOSURE PLATE. SECOND IS AN EXEDY LIGHT WEIGHT RACING FLYWHEEL. IT'S BILLET CHROMOLY STEEL AND SFI CERTIFIED. IT'S DESIGNED TO REDUCE WEIGHT AND ENHANCE AIR FLOW FOR BETTER COOLING. THE INPUT SHAFT FOR THE TREMEC HAS 26 SPLINES, WHICH IS DIFFERENT THAN THE FACTORY GETRAGS. SO A DISC IS NEEDED. THIS IS EXEDY'S STAGE TWO CERAMMETALLIC DISC. IT'S SUITABLE FOR THE STREET, CIRCUIT, DRIFT, AND RALLY USE. DRIVABILITY IS SIMILAR TO A STOCK CLUTCH. THE PRESSURE PLATE WRAPS UP THIS KIT. IT HAS A 40 PERCENT CLAMP LOAD OVER THE FACTORY PIECE. IT FALLS UNDER EXEDY'S RACING LINE. ENCLOSING THE CLUTCH IS THE SFI APPROVED BELL HOUSING. THIS IS AN IMPORTANT PIECE TO PROTECT THE DRIVER IN THE UNLIKELY EVENT OF A CLUTCH FAILURE. ATTACHED TO IT IS THE MAGNUM XL TRANSMISSION. IT WENT RIGHT INTO PLACE WITH NO MODIFICATIONS TO THE CAR. LINKING THE TRANS TO THE REAR DIFFERENTIAL IS A REQUIRED ONE PIECE DRIVESHAFT. THIS ONE WAS BUILT BY PRECISION SHAFT TECHNOLOGIES, OR PST FOR SHORT. IT'S RATED TO 1,000 HORSEPOWER. LAST IS A HOOKER BLACKHEART STAINLESS STEEL AXLE BACK EXHAUST SYSTEM. A STRAIGHT THROUGH MUFFLER DESIGN MAXIMIZE FLOW AND REPORTS AN AGGRESSIVE TONE. FOR STYLING, FOUR INCH DUAL WALL POLISHED TIPS ROUND IT OUT. UP FRONT AND DOWN LOW IS A NEW HAND LAID CARBON FIBER SPLITTER FROM RK SPORT. MARINE CLEAR GEL COAT HAS UV PROTECTION TO ELIMINATE FADE FROM THE SUN. IT'S A DIRECT BOLT ON AND FITS VERY WELL. THIS DIRECT MOUNTED SHORT THROW SHIFTER IS TOPPED OFF WITH A BILLET SIX SPEED KNOB SPORTING THE AMERICAN POWERTRAIN LOGO. NOW IT REPLACES THE GETRAG SLOPPY FEELING SHIFTER ASSEMBLY FOR QUICKER AND MORE ACCURATE GEAR CHANGES. THERE YOU HAVE IT. ONE 2016 RISLONE MUSTANG SWEEPSTAKES CAR. WE ADDRESSED THE POWER, HANDLING, APPEARANCE, AND BRAKING DEPARTMENTS WITH PARTS FROM A LOT OF GREAT COMPANIES. EVERYONE CAME TOGETHER TO MAKE ONE LUCKY PERSON'S LIFE A LITTLE BIT HAPPIER. NOW TO BE THE LUCKY ONE YOU'VE GOT TO LOG ONTO RISLONE DOT COM OR POWERNATION TV DOT COM AND ENTER TO WIN. IT'S THAT EASY.

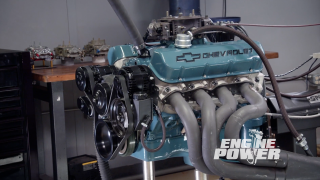

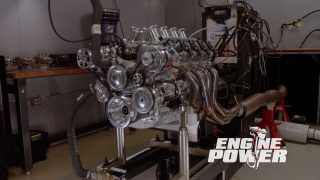

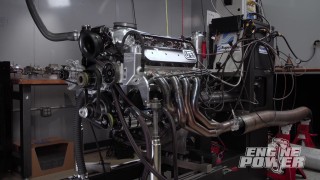

(PAT)>> THIS IS A SUBJECT WE CONSTANTLY GET ASKED ABOUT. SO WE DECIDED TO GIVE A LITTLE REFRESHER ON HOW IT'S DONE, AND THIS PROCESS IS THE SAME WITH ANYTHING THAT USES A DISTRIBUTOR TO LIGHT THE FIRE. THE MOST IMPORTANT STEP IS THE FIRST ONE IN THIS OPERATION. THE ENGINE MUST BE APPROACHING TOP DEAD CENTER ON A COMPRESSION STROKE BECAUSE THE CRANK SHAFT SPINS TWICE AS MANY TIMES AS THE CAM SHAFT, TDC ON THE BALANCER WILL OCCUR AT TWO DIFFERENT PLACES. ONE ON A COMPRESSION STROKE AND THE OTHER ON SPLIT OVERLAP. THAT MEANS ON THE COMPRESSION STROKE BOTH VALVES ARE CLOSED, AND ON SPLIT OVERLAP BOTH VALVES ARE OPEN. WHEN THE DISTRIBUTOR IS PUT IN AT TDC ON SPLIT OVERLAP IT IGNITES THE AIR/FUEL MIX AT THE WRONG TIME, WHEN BOTH VALVES ARE OPEN. THE BURNING AIR/FUEL MIX IS NOT CONTAINED IN A SEALED COMBUSTION CHAMBER, AND HAS AN AVENUE TO TRAVEL ALL THE WAY UP THE INTAKE PORT, THROUGH THE VENTURI OF THE CARBURETOR, AND BOOM, INSTANT FIREBALL. THAT'S WHAT'S GOING ON WHEN SOMEONE SAYS THEY HAVE A DISTRIBUTOR IN 180 OUT. TO KEEP THAT FROM HAPPENING WE WILL REMOVE NUMBER ONE SPARK PLUG AND PUT A FINGER OVER THE HOLE. TURN THE ENGINE OVER UNTIL AIR STARTS TO RUSH OUT, TRYING TO PUSH PAST YOUR FINGER. NOW LOOK AT THE BALANCER. IT SHOULD BE COMING UP ON THE TIMING MARKS. I TURNED THE ENGINE TO 30 DEGREES BEFORE IT GETS TO TOP DEAD CENTER. IF THE VALVE COVER IT'S EASY TO DETERMINE WHERE TDC IS LOCATED ON NUMBER ONE CYLINDER BECAUSE THE ROCKER ARMS WILL NOT BE MOVING WHEN YOU'RE TURNING THE ENGINE. NOW YOU'RE READY FOR DROP IN. NOW YOU HAVE TO ORIENT THE DISTRIBUTOR WHERE YOU WANT THE WIRES TO ROUTE FOR NUMBER ONE. I KNOW IT'S TEMPTING JUST TO DROP IT IN AND WIRE FROM THERE, BUT THAT'S NOT THE PROPER WAY TO DO IT. MARK BOTH THE CAP AND THE HOUSING TO REFERENCE WHERE NUMBER ONE WIRE WILL GO. THEN DROP IN THE DISTRIBUTOR. IT WILL INDEX THE CAM GEAR FIRST, AND THE OIL PUMP DRIVE SECOND. IF IT DOESN'T INDEX THE OIL PUMP DRIVESHAFT DON'T WORRY. TURN THE ENGINE OVER UNTIL YOU FEEL IT GO IN ITS PLACE. THERE'S NO NEED TO PULL THE ENTIRE ASSEMBLY OUT AND TRY TO ALIGN THE DRIVESHAFT WITH A SCREW DRIVER OR A HEX DRIVE. ONCE IT IS INDEXED IN THE CAM BAR, THE ROTOR'S POSITION IS FIXED AND ALL IT HAS TO DO IS DROP DOWN ON THE DRIVE. ALL THAT'S LEFT IS TO WIRE IT, AND FIRE IT. [ engine starts ]

(PAT)>> LOOK MOM, NO FLAMES! [ engine idling ]

Show Full Transcript

(PAT)>> AND IT'S GONNA MAKE A STATEMENT. WE'RE INSTALLING ONE OF PRO CHARGER'S STAGE TWO KITS ON THE CAR THAT UTILIZES THEIR NEW PONEX SUPERCHARGER. NOW IT'LL MAKE 10 POUNDS OF BOOST WITH THE SUPPLIED PULLEYS, AND AT 10 PSI THIS FIVE LITER WILL MAKE OVER 700 HORSEPOWER, WHICH IS PRETTY IMPRESSIVE, AND MIKE HAS ALREADY GOTTEN STARTED ON THE INSTALL. SO WHAT DO YOU HAVE ACCOMPLISHED SO FAR?

(MIKE)>> SO FAR I'VE GOT THE AIR BOX OUT OF THE WAY, THE SOUND TUBE THAT GOES TO THE FIREWALL, COOLANT'S DRAINED, THE FRONT FASCIA'S READY TO COME OFF, AND I WENT AHEAD AND PUT THE NEW THERMOSTAT HOUSING ON.

(PAT)>> FANTASTICAL, LET'S GET THE HOOD OFF FOR A LITTLE MORE ELBOW ROOM AND WE'LL GO FROM THERE.

(MIKE)>> FOUR HANDS ARE BETTER THAN TWO.

(PAT)>> I LIKE IT.

(MIKE)>> BEING CAREFUL WHEN REMOVING THE FASCIA IS A MUST. IT'S A PAINTED BODY PANEL. YOU DON'T WANT TO SCRATCH OR DAMAGE IT IN ANY WAY. BODY SHOP REPAIRS ARE EXPENSIVE.

(PAT)>> JEEZ LOUISE!

(MIKE)>> NEXT TO COME OFF IS THE COOLANT RESERVOIR. A FEW HOSES NEED TO BE REMOVED, AS WELL AS TWO 10 MILLIMETER FASTENERS. IT'S NOT BEING REUSED. INCREASING THE HORSEPOWER LIKE WE'RE GOING TO DO WITH THE SUPERCHARGER MEANS WE HAVE TO ADDRESS THE FUEL SYSTEM. NOW PRO CHARGER INCLUDES BRAND NEW 95 POUND AN HOUR INJECTORS IN THE SYSTEM. NOW THESE THINGS ARE FLOW TESTED AND MATCHED UP IN GROUPS OF EIGHT FOR EVEN DISTRIBUTION ACROSS BOTH BANKS. WE HAVE TO GET THE OLD ONES OUT TO GET THESE IN. THE BRACKETS AND FOAM INSULATORS THAT ARE OVER THE FUEL RAILS COME OFF FIRST. NOW DISCONNECT THE ELECTRICAL CONNECTORS FROM THE INJECTORS. WITH A RAG UNDER THE SUPPLY LINE, DISCONNECT IT AND LET THE RAG SOAK UP ANY FUEL THAT COMES OUT. WITH THE FOUR BOLTS SECURING THE RAIL REMOVED, LIFT IT OFF THE ENGINE.

(PAT)>> HERE'S A QUICK TIP. WHEN YOU'RE CHANGING OUT INJECTORS, LEAVE THEM IN THE RAIL AND DO IT AWAY FROM THE VEHICLE. REASON BEING YOU COULD INADVERTENTLY FILL AN OPEN HOLE WITH GASOLINE BECAUSE WHEN YOU PULL THE INJECTOR OUT GAS FROM THE RAIL CAN RUN DOWN IN A CYLINDER, AND IF THAT HAPPENS AT BDC ON A COMPRESSION STROKE, WHEN YOU PUT IT BACK TOGETHER AND START THE VEHICLE YOU CAN POTENTIALLY BEND A CONNECTING ROD BY HYDROLOCKING IT, AND THAT WILL RUIN YOUR DAY. SWAPPING THE INJECTORS IS EASY. MAKE SURE THE ORINGS ARE LUBED, AND THEY'LL GO RIGHT IN. THE RETAINING CLIPS PUSH ON FROM THE BACK SIDE. NOW THE FUEL RAIL ASSEMBLY IS REPOSITIONED MAKING SURE THE INJECTOR SEATS ALL THE WAY DOWN IN THE MANIFOLD'S INJECTOR BOSSES. FINALLY ALL THE FACTORY PIECES CAN GO BACK ON THE SAME WAY THEY WERE REMOVED.

(MIKE)>> UP FRONT THE PLASTIC RADIATOR SHROUDS CAN BE REMOVED. THERE'S A RIGHT AND LEFT SIDE. PRO CHARGER'S CRANK PULLEY HAS AN EIGHT RIB BELT GROOVE. NOW THIS ATTACHES TO THE FACTORY PULLEY IN TWO DIFFERENT WAYS. THE FIRST IS A SUPPLIED BALANCER BOLT THAT COMES IN THE PRO CHARGER KIT. THE SECOND ARE THESE AWESOME LITTLE CAM LOCKS THAT WEDGE THEMSELVES BETWEEN THE FACTORY PULLEY. THAT KEEPS THE PRO CHARGER ONE FROM ROTATING DUE TO THE FORCE OF THE SUPERCHARGER BELT. THEY'RE ATTACHED TO THE BACK SIDE OF THE PULLEY WITH SUPPLIED HARDWARE. MAKE SURE THE CAM LOCKS ARE POSITIONED AWAY FROM EACH OTHER BECAUSE EACH PAIR STRADDLES ONE OF THE STOCK BALANCER'S WEBS.

(PAT)>> THE PRO CHARGER PIECE IS NOW PLACED IN THE CENTER OF THE STOCK BALANCER. THE NEW BALANCER BOLT IS HAND TIGHTENED, AND THE NEW PULLEY IS ROTATED COUNTER CLOCKWISE UNTIL THE CAM LOCKS STOP IT FROM ROTATING. LIGHTLY TIGHTEN THE BALANCER BOLT, TORQUE THE CAM LOCK BOLTS TO 28 POUND FEET, AND FINALLY TIGHTEN THE BALANCER BOLT TO 35 POUND FEET PLUS 90 DEGREES.

(MIKE)>> NEXT THE SUBBRACKET IS BOLTED TO THE TIMING COVER USING SUPPLIED BOLTS. THE RADIATOR BRACKETS ARE REMOVED NEXT SO WE CAN SLIP THESE RUBBER ISOLATORS OVER THE RADIATOR MOUNTING POST. NOW THE NEW RADIATOR BRACKETS ARE INSTALLED. THEY MOVE THE RADIATOR AWAY FROM THE ENGINE FOR SUPERCHARGER CLEARANCE. A HEX STANDOFF IS THREADED ONTO THE ALTERNATOR STUD, AND THE SUPERCHARGER BRACKET ASSEMBLY IS PUT IN PLACE. THIS BRACKET IS NO JOKE. IT'S SUPER SOLID AND ENGINEERED FOR STRENGTH AND DURABILITY. IT IS POSITIONED IN FRONT OF THE DRIVER'S SIDE CYLINDER HEAD AND ATTACHES WITH FOUR FASTENERS FOR A RIGID, ROCK SOLID MOUNT.

(PAT)>> NOW IT'S TIME TO PREP THE SUPERCHARGER. THIS IS THEIR NEW PONEX, WHICH IS AN IMPROVED DESIGN OVER ITS PREDECESSOR, THE PONESCONE. THE IMPELLER AND COMPRESSOR HOUSING HAVE BEEN IMPROVED FOR BETTER EFFICIENCY AND PERFORMANCE, WITH GAINS OF OVER 50 HORSEPOWER. IT'S DESIGNED TO SUPPORT OVER 800 HORSEPOWER AND HAS A 90 MILLIMETER INDUCER. IT'LL FLOW UP TO 1,275 CFM AND HAS A MAXIMUM IMPELLER SPEED OF 65,000 RPM. THIS IS A SELF CONTAINED UNIT, MEANING IT DOES NOT USE THE ENGINE'S OIL TO LUBRICATE THE SUPERCHARGER. SO THERE'S NO TAPPING INTO THE OIL PAN. FOR EASY DRAINING WHEN IT NEEDS LUBE SERVICE A DRAIN LINE IS ATTACHED TO A FITTING AT THE BOTTOM OF THE SUPERCHARGER. NOW WE CAN ADD ONE SIX OUNCE BOTTLE OF SUPERCHARGER OIL. WHEN WE COME BACK THIS BOOST PRODUCER IS MEETING ITS FINAL DESTINATION.

(MIKE)>> WE'RE BACK WITH THE RISLONE MUSTANG BUILD. THE ENGINE BAY IS PREPPED AND READY FOR THE SUPERCHARGER. IT'S ATTACHED USING SIX SOCKET HEAD CAP SCREWS. IT IS NECESSARY TO ACTUATE THE TENSIONER TO GET TO ALL THE FASTENER HOLES. NOW THE BELT IS ROUTED OVER THE CRANK PULLEY AND UP TO THE PRO CHARGER ONE. A SUPPLIED IDLER SHAFT IS INSERTED INTO THE FACTORY IDLER PULLEY, AND THE PRO CHARGER PULLEY IS ATTACHED TO THE SHAFT WITH NEW HARDWARE. TENSIONING THE BELT IS SIMPLE. TURN THE BRASS COLLAR COUNTER CLOCKWISE UNTIL THE FIRST ALIGNMENT MARKS ON THE TENSIONER BODY ALIGN. UNFORTUNATELY THE CAMERA CAN'T SEE IT. NOW TIGHTEN THE PIVOT BOLT. TURN THE BRASS COLLAR CLOCKWISE TO UNLOAD THE TENSION FROM THE JACK SCREW AND FINALLY TIGHTEN THE JACK SCREW MOUNTING BOLT. KEEPING THE INLET AIR TEMPS IN CHECK IN A BOOSTED APPLICATION IS CRITICAL TO MAKING BIG POWER. NOW PRO CHARGER HANDLES THAT IN AWESOME FASHION. THIS IS THEIR STAGE TWO INTERCOOLER THAT USES A FOUR AND A HALF INCH CORE AND HAS A TON OF SURFACE AREA. NOW THIS BOSS IS WHERE THE MASS AIR SENSOR MOUNTS, AND WITH THE BRACKETS ALREADY INSTALLED IT'S READY TO MOUNT TO THE CAR. IT GOES IN FROM THE BOTTOM. BE CAREFUL AND MAKE SURE YOU DON'T GOUGE THE CONDENSER. THE BRACKETS SLIDE OVER THE BUMPER TO FRAME BOLTS, AND ARE SECURED WITH SUPPLIED NUTS. THE MASS AIR SENSOR CAN BE INSTALLED NOW. IT ONLY GOES IN ONE WAY. A HARNESS EXTENSION IS SUPPLIED SINCE THE SENSOR IS MOVED FAR AWAY FROM ITS ORIGINAL LOCATION. HERE'S A LOOK AT THE SCHEMATIC IN THE PRO CHARGER MANUAL OF THE INTERCOOLER AND ITS PIPING. IT ALL FITS JUST HOW LOOKS, REALLY GOOD. THE ROUTING GOES FROM THE OUTLET OF THE SUPERCHARGER DOWN AND AROUND TO THE INLET OF THE INTERCOOLER. NOW THIS INTERCOOLER WILL SUPPORT UP TO 1,200 HORSEPOWER. THE REASON THIS SUPERCHARGER SYSTEM IS SO EFFICIENT IS YOU'LL ONLY SEE AN EIGHT TO 10 DEGREE RISE OVER AMBIENT TEMPERATURE ON 10 POUNDS OF BOOST, AND THAT'S PRETTY IMPRESSIVE. FROM THE OUTLET OF THE INTERCOOLER THE PIPING RUNS BACK UP TO THE THROTTLE BODY. A VACUUM MANIFOLD IS SUPPLIED TO GET A VACUUM SOURCE LOCATION FOR THE PURGE VALVE AND BOOST GAUGE, IF YOU PLAN ON RUNNING ONE IN THE CAR. THIS LINE WENT FROM THE AIR INLET TUBE TO THE VACUUM TREE. IT CAN BE REMOVED AND DISCARDED. NOW THE MANIFOLD IS ATTACHED TO THE TREE USING A THREEEIGHTHS HOSE. A ONE AND A HALF INCH 90 DEGREE HOSE IS PLACED OVER THE INTERCOOLER TUBE'S BUNG, AND A PRO FLOW SURGE VALVE IS ATTACHED TO IT. IT CAN BE MOUNTED IN ANY DIRECTION. PROTECTING IT FROM THE ELEMENTS IS A PRO CHARGER FILTER. A THREESIXTEENTHS VACUUM HOSE IS CONNECTED TO THE VALVE, AND THE OTHER END TO THE VACUUM MANIFOLD. MAKE SURE THIS LINE IS ROUTED WITHOUT TIGHT BENDS AND AWAY FROM SHARP EDGES. A 90 DEGREE ELBOW IS PLACED ON THE SUPERCHARGER INLET. THE OPEN END POINTS INTO THE DRIVER'S SIDE WHEEL WELL. TUBE NUMBER 379 IS NEXT. IT ATTACHES TO THE 90 DEGREE ELBOW. MAKE SURE THE VACUUM "T" IS POINTED TOWARD THE SUPERCHARGER. A CONICAL AIR FILTER IS ATTACHED TO THE OPEN END OF THE PIPE. WE'LL BE RIGHT BACK.

(MIKE)>> WE'RE BACK AND GETTING EXTREMELY CLOSE TO HAVING THE PRO CHARGER STAGE TWO SYSTEM INSTALLED. UP NEXT IS THE PCV SYSTEM. START BY DISCONNECTING THE LINE ON THE BIG PORT BEHIND THE THROTTLE BODY. NOW CAP IT OFF WITH A VACUUM CAP AND CLAMP. REMOVE THE FACTORY PLASTIC LINES THAT CONNECT TO EACH VALVE COVER VENT. I LIKE TO REMOVE THE FITTING FROM THE PLASTIC LINE THAT WENT TO THE VALVE COVER. IT'S ORINGED AND BARBED, SO THE NEW RUBBER HOSE FITS ON IT TIGHT, AND RUN A PIECE OF SUPPLIED FIVEEIGHTHS VACUUM HOSE FROM THE PASSENGER VALVE COVER ACROSS THE FRONT OF THE RADIATOR AND INSTALL A BRASS UNION IN THE END. ANOTHER FIVEEIGHTHS HOSE GOES ON THE DRIVER'S SIDE VALVE COVER VENT AND RUNS DOWN TO THE PLASTIC "T". THE HOSE WITH THE BARB GETS A SHORT EXTENSION AND GOES TO THE OTHER SIDE OF THE "T". AT THE BACK OF THE ENGINE WE CAN REMOVE THE DIAPHRAGM BENT LINE AT THE "Y", AND PULL IT OUT FROM UNDER THE INTAKE MANIFOLD. CUT THE DRIVER'S SIDE PCV HOSE AND SLIP IN THIS "T". NOW CONNECT THE SUPPLIED THREEEIGHTHS RUBBER HOSE TO THE OPEN BARB AND RUN IT TO THE "Y" AT THE BACK OF THE ENGINE. THE FIVEEIGHTHS HOSES WE JUST RAN ARE PART OF THE PCV SYSTEM, OR POSITIVE CRANK CASE VENTILATION. NOW HOW IT WORKS IS AS THE ENGINE RUNS A LITTLE BIT OF PRESSURE BYPASSES THE RINGS AND GETS INTO THE CRANK CASE. NOW AS THAT PRESSURE BUILDS IT NEEDS A PLACE TO GO. SO IT COMES OUT OF THE TOP OF THE VALVE COVERS. FROM THERE IT RUNS OVER TO THE "T" IN THE INTAKE TUBE. NOW IT'S PULLED INTO THE INTAKE MANIFOLD FROM THAT POINT AND BURNED WITH THE AIR/FUEL MIXTURE. PRO CHARGER ALSO ADDRESSES THE FUEL PUMP BY INCLUDING THIS JMS POWER MAX VOLTAGE BOOSTER THAT IS DESIGNED TO PROVIDE UP TO AN 85 PERCENT INCREASE IN FUEL DELIVERY. IT'S TIGHTENED FROM THE BOTTOM. WITH IT MOUNTED, THE GROUND IS RAN TO THE REAR TRUNK PANEL. WITH THE SEAT BOTTOM REMOVED, LOCATE THE FUEL PUMP DRIVER MODULE. CUT THE PURPLE WIRE WITH THE GREEN TRACER IN HALF. NOW THE WHITE WIRE COMING IN FROM THE BOOSTAPUMP GOES TO THE PURPLE WIRE ON THE CONNECTOR SIDE. THE RED WIRE FROM THE BOOSTER PUMP GOES TO THE OTHER END OF THE PURPLE WIRE. NOW WE ONLY HAVE ONE MORE CONNECTION TO MAKE. BACK AT THE ENGINE A PLUG IS REMOVED FROM THE VACUUM MANIFOLD AND REPLACED WITH THIS PRESSURE SWITCH FROM THE VOLTAGE BOOSTER KIT. FINALLY THE NEW COOLANT RESERVOIR CAN BE BOLTED IN, AND THE COOLANT LINES ATTACHED. NEW PLUGS ARE RECOMMENDED. THESE ARE ONE HEAT RANGE COOLER THAN THE FACTORY ONES. THE GAP IS ALSO TIGHTENED UP TO 35 THOUSANDTHS. THE COIL UNPLUG DESIGN MAKES CHANGING THEM A QUICK JOB. I SENT THE FACTORY TUNE FILE TO PRO CHARGER. WITHIN A DAY THEY HAD THE NEW FILE SENT BACK. I'M USING AN NGAUGE TO LOAD IT INTO THE ECM. THIS PROCESS TAKES ABOUT EIGHT MINUTES, BUT IT ONLY TAKES A SECOND TO PUSH THE START BUTTON AND HEAR THIS. [ engine fires up and idles ]

(MIKE)>> LOOKS GOES WITH PERFORMANCE. NO MORE FACTORY HOOD. THIS IS RK SPORT'S RAM AIR FOR '15 AND UP MUSTANGS. IT'S FULLY FUNCTIONAL AND CONSTRUCTED FROM HAND LAID HIGH TEMP CARBON FIBER. IT'S ALSO REINFORCED WITH FIBERGLASS FOR STRUCTURAL RIGIDITY AND HAS A MARINE CLEAR GEL COAT FINISH WITH UV PROTECTION. IT INSTALLS USING THE FACTORY HARDWARE AND FITS EXTREMELY WELL. THE REAR SPOILER IS ALSO HAND LAID CARBON FIBER AND SHARES THE SAME BENEFITS AS THE HOOD. THIS IS A DIRECT REPLACEMENT FOR THE FACTORY WING. FITMENT IS AWESOME.

(MIKE)>> WELCOME BACK! A LOT HAS HAPPENED SINCE YOU'VE BEEN GONE. FIRST UP IS THIS AWESOME FORM FIT CAR COVER FROM COVER CRAFT. IT WAS MADE FOR OUR SWEEPSTAKES AND SPORTS THE RISLONE LOGO. NOW IT'S THE MOST LUXURIOUS INDOOR COVER THEY OFFER. IT LITERALLY FITS LIKE A GLOVE AND THE SUPER SOFT INSIDE PAMPERS FINE PAINT FINISHES. IT HAS A FOUR YEAR WARRANTY AND IS AVAILABLE IN SIX COLORS. CHECK OUT COVER CRAFT DOT COM FOR ALL THEIR PRODUCTS AND COVER STYLES. WE ALSO HAD A SLICK STRIPE PACKAGE PUT ON THE CAR. THESE RACING STRIPES ADDED A TON OF ATTITUDE TO THIS S-550. IT REALLY SETS IT APART FROM ALL THE OTHER STANGS OUT THERE. UNDERNEATH PAT AND I REMOVED THE TRANSMISSION, WHICH LEFT A BIG VOID, BUT THAT WON'T LAST LONG. THE FACTORY TRANSMISSION IS CALLED A GETRAG MT-82. NOW IT HAS A LIMITED PERFORMANCE ENVELOP WHEN IT COMES TO MUSTANGS THAT MAKE A LOT OF HORSEPOWER. NOW THIS TRANNY WILL WORK GREAT FOR DAILY DRIVERS IN CARS WITH SIMPLE BOLT ONS, BUT FOR THE POWER LEVEL WE HAVE IN OUR MUSTANG THIS THING NEEDS TO BE UPGRADED.

(PAT)>> AMERICAN POWERTRAIN NOW OFFERS A BOLT IN TRANSMISSION UPGRADE KIT FOR 2005 AND UP MUSTANGS. IT WILL CONVERT A FIVE SPEED CAR TO A SIX SPEED CAR, AND GIVE YOU A MUCH STRONGER TRANSMISSION FOR THE GETRAG EQUIPPED CARS THAT ARE MAKING BIG POWER. THE KIT IS CENTERED AROUND THEIR NEW MAGNUM XL TRANSMISSION, WHICH IS A CONTINUATION OF THEIR MAGNUM SIX SPEED. THIS ONE IS RATED AT 700 POUND FEET OF TORQUE, AND THEY'VE ELIMINATED THE RUBBERY SHIFT LINKAGE TO A DIRECT THROW SHIFTER. THE KIT COMES WITH AN SFI APPROVED STEEL BELL HOUSING, CROSS MEMBER, TRANS MOUNT, SHIFTER AND BALL, AND A SPEEDOMETER INTERFACE. NOW THE SYSTEM USES STOCK HYDRAULICS BUT YOU WILL HAVE TO SWITCH TO A 26 SPLINE CLUTCH DISC AND GET A CUSTOM ONE PIECE DRIVESHAFT.

(MIKE)>> THE FIRST PART TO GO ON IS THE ENCLOSURE PLATE. SECOND IS AN EXEDY LIGHT WEIGHT RACING FLYWHEEL. IT'S BILLET CHROMOLY STEEL AND SFI CERTIFIED. IT'S DESIGNED TO REDUCE WEIGHT AND ENHANCE AIR FLOW FOR BETTER COOLING. THE INPUT SHAFT FOR THE TREMEC HAS 26 SPLINES, WHICH IS DIFFERENT THAN THE FACTORY GETRAGS. SO A DISC IS NEEDED. THIS IS EXEDY'S STAGE TWO CERAMMETALLIC DISC. IT'S SUITABLE FOR THE STREET, CIRCUIT, DRIFT, AND RALLY USE. DRIVABILITY IS SIMILAR TO A STOCK CLUTCH. THE PRESSURE PLATE WRAPS UP THIS KIT. IT HAS A 40 PERCENT CLAMP LOAD OVER THE FACTORY PIECE. IT FALLS UNDER EXEDY'S RACING LINE. ENCLOSING THE CLUTCH IS THE SFI APPROVED BELL HOUSING. THIS IS AN IMPORTANT PIECE TO PROTECT THE DRIVER IN THE UNLIKELY EVENT OF A CLUTCH FAILURE. ATTACHED TO IT IS THE MAGNUM XL TRANSMISSION. IT WENT RIGHT INTO PLACE WITH NO MODIFICATIONS TO THE CAR. LINKING THE TRANS TO THE REAR DIFFERENTIAL IS A REQUIRED ONE PIECE DRIVESHAFT. THIS ONE WAS BUILT BY PRECISION SHAFT TECHNOLOGIES, OR PST FOR SHORT. IT'S RATED TO 1,000 HORSEPOWER. LAST IS A HOOKER BLACKHEART STAINLESS STEEL AXLE BACK EXHAUST SYSTEM. A STRAIGHT THROUGH MUFFLER DESIGN MAXIMIZE FLOW AND REPORTS AN AGGRESSIVE TONE. FOR STYLING, FOUR INCH DUAL WALL POLISHED TIPS ROUND IT OUT. UP FRONT AND DOWN LOW IS A NEW HAND LAID CARBON FIBER SPLITTER FROM RK SPORT. MARINE CLEAR GEL COAT HAS UV PROTECTION TO ELIMINATE FADE FROM THE SUN. IT'S A DIRECT BOLT ON AND FITS VERY WELL. THIS DIRECT MOUNTED SHORT THROW SHIFTER IS TOPPED OFF WITH A BILLET SIX SPEED KNOB SPORTING THE AMERICAN POWERTRAIN LOGO. NOW IT REPLACES THE GETRAG SLOPPY FEELING SHIFTER ASSEMBLY FOR QUICKER AND MORE ACCURATE GEAR CHANGES. THERE YOU HAVE IT. ONE 2016 RISLONE MUSTANG SWEEPSTAKES CAR. WE ADDRESSED THE POWER, HANDLING, APPEARANCE, AND BRAKING DEPARTMENTS WITH PARTS FROM A LOT OF GREAT COMPANIES. EVERYONE CAME TOGETHER TO MAKE ONE LUCKY PERSON'S LIFE A LITTLE BIT HAPPIER. NOW TO BE THE LUCKY ONE YOU'VE GOT TO LOG ONTO RISLONE DOT COM OR POWERNATION TV DOT COM AND ENTER TO WIN. IT'S THAT EASY.

(PAT)>> THIS IS A SUBJECT WE CONSTANTLY GET ASKED ABOUT. SO WE DECIDED TO GIVE A LITTLE REFRESHER ON HOW IT'S DONE, AND THIS PROCESS IS THE SAME WITH ANYTHING THAT USES A DISTRIBUTOR TO LIGHT THE FIRE. THE MOST IMPORTANT STEP IS THE FIRST ONE IN THIS OPERATION. THE ENGINE MUST BE APPROACHING TOP DEAD CENTER ON A COMPRESSION STROKE BECAUSE THE CRANK SHAFT SPINS TWICE AS MANY TIMES AS THE CAM SHAFT, TDC ON THE BALANCER WILL OCCUR AT TWO DIFFERENT PLACES. ONE ON A COMPRESSION STROKE AND THE OTHER ON SPLIT OVERLAP. THAT MEANS ON THE COMPRESSION STROKE BOTH VALVES ARE CLOSED, AND ON SPLIT OVERLAP BOTH VALVES ARE OPEN. WHEN THE DISTRIBUTOR IS PUT IN AT TDC ON SPLIT OVERLAP IT IGNITES THE AIR/FUEL MIX AT THE WRONG TIME, WHEN BOTH VALVES ARE OPEN. THE BURNING AIR/FUEL MIX IS NOT CONTAINED IN A SEALED COMBUSTION CHAMBER, AND HAS AN AVENUE TO TRAVEL ALL THE WAY UP THE INTAKE PORT, THROUGH THE VENTURI OF THE CARBURETOR, AND BOOM, INSTANT FIREBALL. THAT'S WHAT'S GOING ON WHEN SOMEONE SAYS THEY HAVE A DISTRIBUTOR IN 180 OUT. TO KEEP THAT FROM HAPPENING WE WILL REMOVE NUMBER ONE SPARK PLUG AND PUT A FINGER OVER THE HOLE. TURN THE ENGINE OVER UNTIL AIR STARTS TO RUSH OUT, TRYING TO PUSH PAST YOUR FINGER. NOW LOOK AT THE BALANCER. IT SHOULD BE COMING UP ON THE TIMING MARKS. I TURNED THE ENGINE TO 30 DEGREES BEFORE IT GETS TO TOP DEAD CENTER. IF THE VALVE COVER IT'S EASY TO DETERMINE WHERE TDC IS LOCATED ON NUMBER ONE CYLINDER BECAUSE THE ROCKER ARMS WILL NOT BE MOVING WHEN YOU'RE TURNING THE ENGINE. NOW YOU'RE READY FOR DROP IN. NOW YOU HAVE TO ORIENT THE DISTRIBUTOR WHERE YOU WANT THE WIRES TO ROUTE FOR NUMBER ONE. I KNOW IT'S TEMPTING JUST TO DROP IT IN AND WIRE FROM THERE, BUT THAT'S NOT THE PROPER WAY TO DO IT. MARK BOTH THE CAP AND THE HOUSING TO REFERENCE WHERE NUMBER ONE WIRE WILL GO. THEN DROP IN THE DISTRIBUTOR. IT WILL INDEX THE CAM GEAR FIRST, AND THE OIL PUMP DRIVE SECOND. IF IT DOESN'T INDEX THE OIL PUMP DRIVESHAFT DON'T WORRY. TURN THE ENGINE OVER UNTIL YOU FEEL IT GO IN ITS PLACE. THERE'S NO NEED TO PULL THE ENTIRE ASSEMBLY OUT AND TRY TO ALIGN THE DRIVESHAFT WITH A SCREW DRIVER OR A HEX DRIVE. ONCE IT IS INDEXED IN THE CAM BAR, THE ROTOR'S POSITION IS FIXED AND ALL IT HAS TO DO IS DROP DOWN ON THE DRIVE. ALL THAT'S LEFT IS TO WIRE IT, AND FIRE IT. [ engine starts ]

(PAT)>> LOOK MOM, NO FLAMES! [ engine idling ]