Building the Beast — Project UnSanctioned Part 4

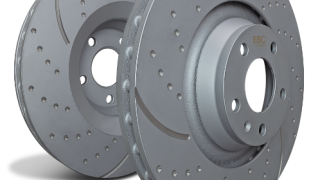

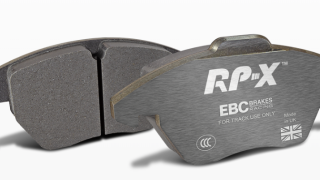

Our 2001 BMW race car gets a set of coilovers, as well as big brake upgrade. Then we change the aerodynamics of our project to give it a fierce look.

Season 5

Episode 12