More Hurst Olds Episodes

Detroit Muscle Featured Projects

Detroit Muscle Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Wilwood Engineering

Disc Brake Kit, Front, Drilled Rotors, Superlite 6 Calipers, Black, Chevy, Kit

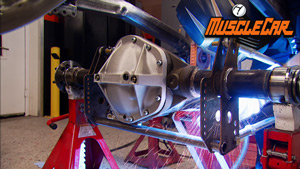

Art Morrison Enterprises

GT-Sport Chassis For 1968-1972 Chevelle

Brad Starks Rod & Customs

Custom Shop focused on high quality work with a full time staff building one-off customs.

Greening Auto Company

Custom designed and manufactured billet wheels

ididit Inc.

Steering Column, Keyless, Tilt, 69-92 Chevelle/El Camino, Steel

Performance Design

Cross-ram style dual plenum, dual throttle intake manifold, all carbon fiber and billet aluminum construction, Fits LS7 Port; LS3 port following release of LS7

The Industrial Depot

The Industrial Depot - Fasteners, Hardware and Shop Supplies