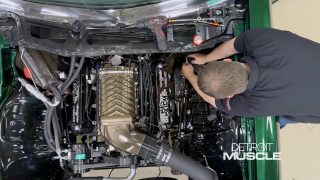

Restoring The ‘71 Chevy Caprice's Heater Box

It’s a heat wave – We restore the heater box on project Fat Stack, and install some air conditioning components to make the ’71 Caprice literally cool.

Season 10

Episode 12