Fat Stack – Part 14: Clean, Mean, and Candy Green

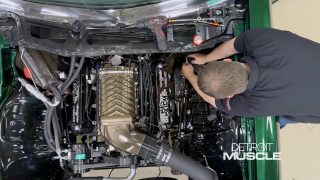

Our 1971 Chevy Caprice, Project Fat Stack, ROARS to life after almost a year of work. Tommy and Peyton give the nitty gritty on exhaust installation and finish the interior. Fat Stack turns heads in downtown Nashville to the delight of the Broadway crowd.

Season 11

Episode 1