More "Iron Animal" 408 Turbo Episodes

Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

ARP

Assembly Lubricant, for Engine Assembly and Fastener Installation, Ultra Torque, 1 Pint, Each

ARP

Bolts, Hex Head, Chromoly Steel, Black Oxide, 8mm x 1.25 RH Thread, 30mm UHL, Set of 5

Chevrolet Performance

Head Gasket, MLS, 4.080 in. Bore, .051 in. Compressed Thickness, Chevy, Small Block, LS3/L92, Each

FAST

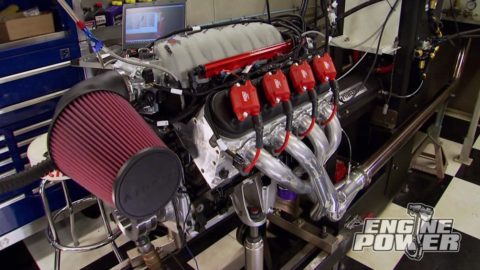

Engine Management System, FAST XFI Crate/Transplant, 58X Reluctor Wheel, Chevy, 6.0L LS, 7.0L LS, Kit for LS2/LS3/LS7 - 2006 & Newer Engines

FAST

Fuel Rails, Billet Aluminum, Red Anodized, Chevy, LS1/LS6 Engines, LSXR 102mm Intake, Kit

FAST

Intake Manifold, Fuel-Injected, Complete, Polymer, Black/Gray, Chevy, 6.2L, LS3, Each

JBA Performance Exhaust Co.

Headers, Competition Ready, Stainless Steel, Silver Ceramic Coated, Chevy, 6.2L, Pair

Summit Racing

Harmonic Balancer, Internal Balance, Steel, Clearcoated, Buick, Cadillac, Chevy, GMC, Hummer, 4.8, 5.3, 6.0L

Trick Flow Specialties

Cylinder Head, GenX 255, CNC Comp Port, Assembled, 69cc CNC Chamber, 448 Lb. Springs, Ti-Retainers, GM LS3, Each

Trick Flow Specialties

Timing Chain and Gear Set, Double Roller, Billet Steel Sprockets, Chevy, 4.8, 5.3, 6.0, 6.2L, 3-Bolt, Set

Trick Flow Specialties

Timing Chain Dampener, Plastic, LS2/LS3, Non-VVT Engines, Includes Adapter Bracket, Kit

ENTER THE GIVEAWAY

PowerNation's Iron Animal 408 Turbo Giveaway Sweepstakes features an LS stroker engine that is capable of producing 850 horsepower and 900 ft. lbs. of torque! The foundation for this project was a fully-machined, 6-liter iron block with parts coming from Summit and Trick Flow, making this performance bad boy worth $20,000! Click the "ENTER THE GIVEAWAY" link for your chance to win the sweepstakes.

Goodson Shop Supplies

Powered Ring Filer with Integral De-burring Wheel

K1 Technologies

GM, LS, 408 Stroker Kit (24 Tooth Reluctor) (Pre-Balanced)

The Industrial Depot

The Industrial Depot - Fasteners, Hardware and Shop Supplies