Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Accel

Spark Plug Wires, Extreme 9000 Ceramic, Spiral Core, 8mm, Black, 90 Degree Boots, Universal, V8, Set

Chevrolet Performance

ZZ572, Engine Assembly, Crate Engine, Chevy, 572, 620 hp, 720R heads, USED

Clevite

Rod Bearing, H Series, Coated, Standard Size, Tri Metal, Chevy, 348, 366, 396, 402, 409, 427, 454, Each

Clevite

Main Bearings, H Series, Standard Size, Tri Metal, Chevy, 396, 402, 427, 454, Set of 5

Comp Cams

Rocker Arms, Shaft Mount, Full Roller, Aluminum, 1.7 Ratio, Chevy, Big Block, Kit

Crane Cams

Lifters, Ultra Pro, Mechanical Roller, Vertical Link Bar, Chevy, 396-454, Set of 16

Crane Cams

Valve Springs, Dual, 1.625 in. O.D., 564 lbs./in. Rate, 1.210 in. Coil Bind Height, Set of 16

Federal-Mogul Corporation

FEL-PRO, Oil Pan Gasket, 1-Piece, Rubber/Steel Core, Chevy, Big Block, Each

Holley

Carburetor, 4 Barrel, Holley Gen 3 Ultra Dominator, Gasoline - Dual Inlet, 1,150 CFM, Tumble Polished, Each

Hooker Headers

Headers, Super Competition, Full-Length, Steel, Painted, Chevy, Pontiac, 396, 402, 427, 454, Pair

Quick Fuel Technology Inc.

Carburetor, Black Diamond Q-Series, 750 cfm, Mechanical Secondary, 4-Barrel, Square Bore, Drag Race, Each

Weiand

Intake Manifold, Hi-Ram, Tunnel Ram, Aluminum, Natural, Dual Square Bore, Chevy, Big Block, Rectangle Port

Crane Cams

Custom grind Camshaft, BB Chevy, SLD. Roller

Goodson Shop Supplies

Select Flex-Hone Diameter: 4.625" (117.5mm)

Goodson Shop Supplies

High Performance Valve Spring Compressor, Pneumatic

The Industrial Depot

Fasteners, Hardware, and Shop Supplies

Video Transcript

(ANNOUNCER)>> TODAY ON

ENGINE POWER WE CHALLENGE OURSELVES TO BUILD A

BIG BLOCK BRACKET RACING MONSTER FROM

LEFTOVER PARTS. YOU WON'T BELIEVE

THE RESULTS.

(MIKE)>> IT'S A LITTLE DIFFERENT NOT HAVING ALL NEW PARTS, HUH?

(PAT)>> THIS IS GONNA BE A GOOD ONE THOUGH.

(MIKE)>> WELCOME TO ENGINE POWER. TODAY WE'RE BUILDING A BIG BLOCK CHEVY BRACKET BLASTER FROM BITS AND PIECES WE'VE HAD LAYING AROUND THE SHOP. NOW WE'RE LIKE A BIG PERCENTAGE OF YOU GUYS THAT HAVE PARTS FROM SEVERAL DIFFERENT ENGINES JUST FLOATING AROUND. ADD A COUPLE OF SPECIFIC ITEMS TO THOSE AND YOU CAN CREATE A SUPER RELIABLE BULLET TO POUND ON AROUND TOWN AND HAVE A REALLY, REALLY CONSISTENT BRACKET ENGINE ON THE WEEKENDS.

(PAT)>> HOW WILL IT ACCOMPLISH THOSE GOALS?

WELL NUMBER ONE IS CUBIC INCHES. THE BIGGER THE ENGINE, THE EASIER IT IS TO MAKE NATURALLY ASPIRATED HORSEPOWER BECAUSE ALL THOSE INCHES MAKE TORQUE AND TORQUE IS WHERE HORSEPOWER IS CALCULATED FROM. THIS PARTICULAR BLOCK HAS A 4.560 BORE AND THE CRANK HAS A 4.375 STROKE, WHICH EQUALS 572 CUBIC INCHES. AND THAT'S BIG BY PRETTY MUCH ANYONE'S STANDARDS. THIS IS A TALL DECK GM 572 SPORTSMAN ENGINE THAT'S BEEN SITTING ON THE SHELF NEXT TO A PILE OF GREASY PARTS FOR QUITE SOME TIME. NUMBER TWO WE'RE USING 93 OCTANE PUMP GAS RIGHT FROM THE LOCAL GAS STATION, WHICH SIMPLIFIES EVERYTHING SINCE WE CAN GET GAS FOR IT ANYWHERE.

AND NUMBER THREE WE HAVE TO HAVE ADEQUATE INDUCTION, WHICH WE HAVE COVERED.

(MIKE)>> THE HEART OF THE INDUCTION ARE CHEVY PERFORMANCE'S BOWTIE 572-R CYLINDER HEADS THAT RECEIVED SPECIAL MESSAGING FROM LIVERNOIS MOTORSPORTS. ON THE DYNO WE'RE GOING TO TEST A SINGLE PLANE HIGH RISE THAT ACCEPTS A SINGLE DOMINATOR AND A TUNNEL RAM THAT IS CAPPED OFF WITH DUAL 4150 CARBS. THE VALVETRAIN IS ALL SOLID ROLLER AND THE CAMSHAFT HAS A SPECIAL FEATURE THAT IS MOSTLY

RECOGNIZED IN THE RACING WORLD. NOW FOR ACCURATE CAM SHAFT TIMING AND EASE OF MAINTENANCE A JESEL BELT DRIVE WILL SIMPLIFY THE TASK OF CHANGING CAMS ON THE DYNO. COMPLIMENTING IT IS AN MSD CRANK TRIGGER. THE FOUNDATION FOR POWER AND RELIABILITY LIES IN THE PARTS WE ALL USE. NOW THIS CRANK IS A 4340 FORGED STEEL UNIT THAT'S DESIGNED TO RUN A ONE PIECE REAR MAIN SEAL AND IT'S INTERNALLY BALANCED. NOW THE JOURNALS HAVE A LARGE RADIUS FOR ADDITIONAL STRENGTH BUT THAT ALSO MEANS A NARROW BEARING MUST BE USED. THE RODS ARE MADE OF THE SAME MATERIAL AS THE CRANK SHAFT, 4340 FORGED STEEL. NOW THEY HAVE A SIX-535 CENTER TO CENTER AND ARE AN HBEAM DESIGN. ARP 2,000 BOLTS WILL KEEP THE CAPS IN PLACE.

(PAT)>> THE STARTING POINT FOR THIS PROJECT IS BLOCK PREP, AND THIS ONE NEEDS SOME TLC DUE TO THE AMOUNT OF RUN TIME IT HAS ON IT.

NOW WE'VE ALREADY MEASURED THE BORES, THE CRANK

JOURNALS, THE RODS AND PISTONS, AND THE DECKS, AND EVERYTHING LOOKS REALLY GOOD. SO THE DECISION WAS MADE TO FRESHEN IT UP WITH NEW RINGS AND BEARINGS, AND PUT IT TOGETHER WITH MOST OF THE PARTS FROM THE PILE.

THE TLC WE MENTIONED ARE ALL STEPS YOU CAN DO AT

HOME, LIKE REFINISHING THE CYLINDERS WITH A FLEX HONE

LIKE THIS ONE WE GOT FROM GOODSON. THE FIRST THING YOU WANT TO DO IS GRAB SOME WD 40 FOR LUBE AND SOME SHOP TOWELS BECAUSE IT

GETS A LITTLE MESSY. WITH THE FLEX HONE INSTALLED IN A VARIABLE FEED DRILL, HERE'S HOW IT'S DONE. SPRAY THE CYLINDER AND FLEX HONE WITH A FEW SHOTS OF WD. GET THE DRILL GOING RIGHT AS THE FLEX HONE GOES IN THE CYLINDER. CHECK YOUR PROGRESS OFTEN BECAUSE SOME BORES MIGHT

NEED MORE ATTENTION THAN OTHERS. I'M RUNNING THE DRILL WIDE OPEN AND CROSS HATCHING THE BORE RATHER QUICKLY. THE END RESULT WILL BE BETWEEN A 35 AND 45 DEGREE CROSS HATCH LIKE THIS. TINY AND SHALLOW VERTICAL SCRATCHES ARE STILL PRESENT BUT WON'T EFFECT HOW THE ENGINE PERFORMS. THE IMPORTANT PART IS THE BORES ARE SURFACE

RECONDITIONED FOR THE NEW RINGS. DON'T LET THE HONE STOP INSIDE THE BORE. KEEP IT MOVING UP AND DOWN AS WELL AS ROTATING ALL THE TIME. THE REASON WE CAN USE THIS CYLINDER FINISHING METHOD IS BECAUSE THE CYLINDERS WE HAVE ARE STRAIGHT, ROUND, AND THE PROPER SIZE. IF THE BORES WERE HEAVILY WORN IT WOULD NEED TO BE

BORED AND HONED AT A MACHINE SHOP. WHILE WE HAVE THE DRILL IN HAND WE'RE GONNA DO THE LIFTER BORES AS WELL, JUST WITH A SMALLER VERSION.

THE SAME TECHNIQUE IS USED AS THE CYLINDER BORES. JUST REMEMBER YOU'RE NOT TRYING TO CHANGE THE SIZE, JUST REFRESH THE SURFACE FINISH. ANOTHER PREP STEP IS DEBURRING THE BLOCK, WHICH

MEANS REMOVING ALL THE SHARP EDGES AND CASTING LINES. AND THAT HAS A COUPLE OF BENEFITS. THE FIRST BEING YOU HAVE A SAFER BLOCK TO WORK WITH SO YOU DON'T CUT YOURSELF. AND THE SECOND, IT HELPS PREVENT A PLACE FOR A CRACK TO START. A DIE GRINDER AND A CARBIDE BURR ARE THE TOOLS FOR THE JOB.

THESE ARE BOTH FROM MATCO. THE FOCUS IS ON SHARP EDGES AND RAISED CASTING LINES ALL OVER THE BLOCK. BECAUSE THIS ONE'S POWDER COATED, THEY'LL

BE EASY TO FIND.

DON'T USE MUCH PRESSURE, THE BURR DOESN'T LIKE IT. A LIGHT PASS OVER TAKES CARE OF BUSINESS. NOW ALL WE NEED TO DO IS REMOVE THE REST OF THE OIL GALLERY PLUGS. THIS WILL INSURE THE BLOCK GETS CLEANED INSIDE AND OUT IN THE JET WASHER. OUR KUNDAL SNAP TRACK HOIST WILL LOAD IT INTO THE JET WASHER WHERE IT WILL STAY FOR ONE HOUR. THE REST OF THE PARTS ALSO GET A CLEANING, STARTING WITH THE CRANK. IT WILL SIT FOR 15 MINUTES. THEN WE CAN GIVE THE PISTONS AND RODS

THE SAME TREATMENT.

(ANNOUNCER)>> WITH EVERYTHING CLEANED AND PREPPED, THE BUILD BEGINS, THAT'S NEXT!

(MIKE)>> WE'RE BACK AND THIS BUILD IS CONTINUING WITH ASSEMBLY. NOW WE ALREADY CHECK ALL OF OUR MAIN BEARING CLEARANCES AND WE HAVE BETWEEN 27 AND 32 TEN

THOUSANDTHS, WHICH GIVES US THE GREEN LIGHT TO CONTINUE. A UNIQUE FEATURE TO THIS BLOCK IS IT HAS GROOVES IN THE UPPER MAIN SADDLES. THAT ALLOWS EXTRA HOLES TO BE DRILLED IN THE BEARING

ITSELF FOR ADDITIONAL OILING, WHICH INCREASES BEARING LONGEVITY.

USING A POCKET SCALE GET THE LOCATION THE HOLE NEEDS TO BE DRILL IN. TRANSFER THAT TO THE BEARING, AND DRILL A HOLE WITH THE BEARING IN A SECURE SPOT. [ drill spinning ]

(MIKE)>> FINALLY WE'LL USE LARGER BITS TO DEBURR THE HOLE ON EACH SIDE, AND THIS LITTLE BIT OF

RACING TECH IS COMPLETE.

(PAT)>> THESE BEARINGS ARE NARROWED TO CLEAR THE RADIUS ON THE CRANK JOURNAL. WE ORDERED THEM FROM CLEVITE WITH THEIR ANTIFRICTION COATING. WITH A LITTLE ASSEMBLY LUBE ON EACH ONE, THE CRANK IS CAREFULLY LAID INTO THE BLOCK AND THE REAR MAIN SEAL IS POSITIONED. NOW LUBE THE LOWER BEARINGS AND POSITION THE

MAIN CAPS, TAP THEM DOWN, AND LIGHTLY SNUG THEM UP. USING A DEAD BLOW, TAP THE CRANK FROM FRONT TO REAR AND REAR TO FRONT TO SQUARE UP THE THRUST BEARING. NOW TORQUE THE MAINS TO 95 FOOT POUNDS USING EXTREME PRESSURE LUBE, AND THE CRANK IS SECURED.

(MIKE)>> THE NEXT THING TO GO IN THE ENGINE ARE OUR PISTON AND ROD ASSEMBLIES. NOW WE ALREADY FILE FIT OUR MAHLE RING SET. THEY SENT US A SIXTEENTH, SIXTEENTH, THREESIXTEENTH PACKAGE THAT USES A LOW TENSION OIL RING, WHICH WILL FREE UP A LITTLE HORSEPOWER.

NOW WE GAPPED THE TOP RING AT 22 THOUSANDTHS, AND THE SECOND RING AT 24. USING MOTOR OIL, LUBE THE RINGS AND SKIRTS OF THE PISTON, AND DROP THE ASSEMBLY INTO A RING COMPRESSOR.

THE ROD BEARINGS ARE NARROWED AS WELL DUE TO THE RADIUS ON THE JOURNAL. HIGH VISCOSITY ASSEMBLY LUBE WILL PROTECT THEM DURING THE INITIAL FIRE UP. NOW ALIGN THE SETUP WITH THE CYLINDER BORE, AND TAP THEM IN WITH A DEAD BLOW PISTON KNOCKER LIKE THIS. (PAT>> UNDERNEATH, YOU READY?

(MIKE)>> YEP, COME ON.

(PAT)>> BE CAREFUL NOT TO NICK THE JOURNAL AS YOU GUIDE THE BIG END OF THE ROD DOWN TO IT. NOW THE CAP AND ARP 2,000 BOLTS GO IN AND GET SNUGGED DOWN. FINAL TORQUING HAPPENS AFTER THEY'RE ALL IN. FORGED ALUMINUM PISTONS FROM JE FILL THE BORES. THEY'RE A FLAT TOP DESIGN WITH A SINGLE VALVE RELIEF, WHICH MEASURES THREE CC'S DEEP. THIS IS PERFECT FOR OUR PUMP GAS FRIENDLY SETUP SINCE OUR COMPRESSION RATIO CALCULATES TO NINE

POINT SEVEN TO ONE.

(MIKE)>> NOW WE CAN TORQUE THE ROD BOLTS TO 75 POUND FEET.

(PAT)>> THE CAM SHAFT IS NEXT. IT'S FROM THE USED PILE. IT'S A MECHANICAL ROLLER. DURATION AT 50 IS 260 ON THE INTAKE, 270 ON THE EXHAUST WITH 110 DEGREES OF LOBE SEPARATION. LIFT IS 670 ON BOTH SIDES. BOLTING TO IT IS THE DRIVE HUB ADAPTER JESEL SENT SO WE CAN RUN THEIR BELT DRIVE. ON THE FRONT OF THE ENGINE JESEL'S FRONT COVER GOES ON FIRST.

YOU MAY NEED TO CLEARANCE THE BLOCK, OURS WAS ALREADY DONE. THIS CAM HAS A STANDARD FIRING ORDER AND WILL BE SWAPPED OUT FOR A SPECIAL CAM BACK ON THE DYNO AFTER WE SEE WHAT KIND OF POWER THIS ONE MAKES. WITH A SHIM IN PLACE, WE CAN INSTALL THE THRUST

PLATE, WHICH HAS A THIN LAYER OF SILICONE TO PREVENT AN OIL LEAK. THE SEAL STAYS DRY SINCE IT'S TEFLON. WITH IT SNUG WE CAN CHECK THE CAM SHAFT'S END PLAY. JESEL SPECIFIES BETWEEN EIGHT AND 12 THOUSANDTHS. WE ARE IN. [ hammer tapping ]

(PAT)>> THE TIMING MARKS ARE ALIGNED FOR THE CRANK AND CAM, WHICH GETS US READY TO INSTALL THE BELT. IT'S A ROUND TOOTH COG STYLE AND GOES IN WITH THE UPPER PULLEY ASSEMBLY ALL AT ONCE. THAT COMPLETES THE LINK BETWEEN THE CAM AND THE CRANK. THE LAST THING TO DO IS DEGREE THE CAM. UNDERNEATH THE HIGH VOLUME OIL PUMP GOES ON. IT HAS THE PICK UP ATTACHED FOR THE PAN WE'LL USE. SECURING IT IS A SPECIAL STUD THAT WORKS IN

CONJUNCTION WITH THE WINDAGE TRAY. IT GETS POSITIONED ON THE STAND OFFS FROM A FEW OF THE MAIN FASTENERS. ITS JOB IS TO DISRUPT THE VORTEX OF OIL IN THE CRANK

CASE CAUSED BY CRANKSHAFT ROTATION. WITH OUR FEL PRO GASKET IN PLACE, THE EIGHT QUART MOROSO DRAG RACE PAN GOES ON, AND WITH THAT THE SHORT BLOCK IS COMPLETE. REMEMBER WHEN WE SAID WE HAD THE INDUCTION PART COVERED, WELL THIS IS WHAT WE WERE TALKING ABOUT. THIS IS A CHEVY PERFORMANCE CASTING THAT FOUND ITS WAY TO LIVERNOIS MOTORSPORTS, WHERE IT

RECEIVED SOME OF THEIR PORTING MAGIC ON THEIR CNC EQUIPMENT.

LAST TIME THESE WERE ON A BIG INCH BIG BLOCK THEY PRODUCED SIGNIFICANT POWER GAINS. SO WE'RE GONNA SEE WHAT THEY'RE GONNA DO FOR US. THESE SPRINGS AND ALL THE COMPONENTS CAME FROM CRANE CAMS. SO WE SET THE INSTALL HEIGHT AT TWO-100 AND WE'RE READY TO ASSEMBLE THEM. THE SHIM AND LOCATOR ARE FIRST, FOLLOWED BY THE SEAL, WHICH CAN BE A LITTLE TRICKY INSTALLING,

SO BE CAREFUL. NEXT LUBE THE VALVE STEM AND SLIDE IT INTO THE GUIDE IN A ROTATING FASHION SO THE ENTIRE GUIDE IS SLICKED UP. THE DUAL SPRING AND TITANIUM RETAINER IS NEXT, AND IT ALL GETS COMPRESSED WITH OUR MTI SPRING COMPRESSOR FROM GOODSON. NOW PLACE THE LOCKS ON THE STEM AND RELEASE THE COMPRESSOR. THAT'S IT, JUST 15 MORE TO GO. WITH CRANE'S ULTRA PRO LIFTERS INSTALLED IN A 30 THOUSANDTHS THICK COMEDIC HEAD GASKET IN PLACE, THE HEADS GET MATED TO THE BLOCK. WE'LL NEED THE CYLINDER HEAD INSTALLER.

THERE YOU GO. WE'RE TORQUEING THE HEADS TO 75 POUND FEET AND DECLARING LONG BLOCK STATUS.

(ANNOUNCER)>> COMING UP ITS MAKE OR BREAK ON THE DYNO.

(MIKE)>> WE'RE BACK AND OUR 572 CUBIC INCH BRACKET BLASTER IS STRAPPED TO THE DYNO. NOW WE STILL HAVE A FEW THINGS TO DO AND IT'S GONNA HAPPEN FAST. SO MAKE SURE YOU PAY ATTENTION.

STRAPPED TO THE TOP OF THE HEADS ARE COMP CAM'S ONE POINT SEVEN RATIO SHAFT MOUNTED ROCKERS, AND CONTROLLING THEM ARE THE THREEEIGHTHS PUSH RODS. CAST ALUMINUM VALVE COVERS WILL COVER THEM UP. AND FOR INCREASED RING SEAL AND LESS INTAKE CHARGE CONTAMINATION A MISTER GASKET CRANK CASE EVAC KIT HAS BEEN INSTALLED. AND FOR INDUCTION A CHEVY PERFORMANCE HIGH RISE TOPPED OFF WITH A HOLLEY 1,150 CFM DOMINATOR. AN MSD CRANK TRIGGER BOLTS TO THE BALANCER, THE

BRACKET AND PICK UP ARE INSTALLED, AND THE GAP IS SET. WRAPPING UP THE RACY PARTS IS A JESEL FRONT DISTRIBUTOR DRIVE, CAP, AND EXCEL EXTREME 9,000 PORCELAIN BOOTED WIRES. AN ELECTRIC WATER PUMP WILL CIRCULATE THE COOLING JUICE.

AND THE LAST LINK IS THE EXHAUST, TWO INCH HOOKER SUPER COMPS THAT FLOW INTO THREE AND A HALF INCH PIPE TO DIRECT THE EXHAUST GASES OUT OF THE ENGINE.

WITH 93 OCTANE SHELL PUMP GAS FILLING THE CELL AND ALL THE FLUIDS PRIMED, HERE'S THE INITIAL FIRE UP. [ engine starts and revs ]

(MIKE)>> THAT SOUNDS LIKE BIG BLOCK POWER RIGHT THERE. PAT IS CONFIRMING THE TIMING IS AT 32 DEGREES. SINCE THE JESEL DISTRIBUTOR DRIVE IS UP FRONT, WE PUT AN MSD DISTRIBUTOR IN TO DRIVE THE OIL PUMP AND COMPLETE THE OIL CIRCUIT OUT BACK. WITH A BREAK IN AND WARM UP CYCLE BEHIND US.

(PAT)>> BIG BLOCK CHEVY TAKE ONE.

(MIKE)>> HERE'S WHAT A 572 INCH RAT WITH NINE POINT SEVEN TO ONE COMPRESSION AND 93 OCTANE DOES ON THE PUMP FROM 3,000 TO 5,000 RPM. LOADED UP GOOD, NICE AND CLEAN. THE PAINT'S STILL BURNING OFF THE HEADERS A LITTLE BIT. 623 ON POWER.

(PAT)>> THAT AIN'T BAD.

(MIKE)>> AND CLIMBING LIKE A MONSTER, 656 FOOT POUNDS. YOU WANT TO STEP UP RPM?

(PAT)>> YEAH LET'S STEP UP RPM.

(MIKE)>> THREE TO 65, ACTIVATED, HERE WE GO. [ engine revving ]

(PAT)>> THAT LOOKED PRETTY DECENT.

(MIKE)>> GOSH IT SOUNDS SO GOOD.

(PAT)>> THAT LOOKED PRETTY DECENT RIGHT THERE. THAT'S PRETTY NICE!

(MIKE)>> 672 HORSE, 657 POUND FEET. WELL LET'S SEE HERE. WE'VE GOT TWO OTHER SCENARIOS WE'VE GOT TO DO.

THE CAM SHAFT WITH THE FOURSEVEN SWAP AND THE TUNNEL RAM WITH TWO FOURS. SO LET'S GO AHEAD AND JUST PUT 36 DEGREES IN IT, SEE WHAT IT DOES WITH THIS SETUP, AND CALL IT A GAME AND DO THE CAM SWAP.

(PAT)>> I'M ALL OVER THAT.

(MIKE)>> MAN, SHE FIRES UP EASY. SAME SWEEP, THREE TO 65. 674, 660.

(PAT)>> SOUNDS MEAN!

(MIKE)>> I SAY WE CHANGE THE STICK, RUN IT ONCE WITH THIS INTAKE, THEN DO THE TUNNEL RAM AND LET THESE FOLKS SEE WHAT THE TUNNEL RAM IS CAPABLE OF.

(PAT)>> WE'RE GONNA FIND OUT.

(MIKE)>> COOL!

(PAT)>> WE CONCLUDED THE STANDARD CAM RUNS AND GOT 674 HORSEPOWER AND 660 POUND FEET OF TORQUE. BUT LIKE ALL THINGS THERE IS ROOM FOR IMPROVEMENT. THIS NEW BUMP STICK IS 14 DEGREES LARGER EVERYWHERE AND IS ON 114 DEGREES OF LOBE SEPARATION.

LIFT IS 100 THOUSANDTHS MORE AT THE VALVE. PLUS IT HAS A FOURSEVEN FIRING ORDER SWAP BUILT IN. WHAT WE MEAN BY A FOURSEVEN SWAP IS WE'VE CHANGED THE FIRING ORDER OF THE CAM, AND THAT DOES A COUPLE OF DIFFERENT THINGS. ONE, IT REDUCES TORSION ON THE CRANK SHAFT AND THAT HELPS REDUCE MAIN BEARING LOADING BUT JUST AS IMPORTANT IT CHANGES THE PULSES BACK INTO THE INTAKE MANIFOLD AND THAT HELPS EVEN OUT FUEL DISTRIBUTION. NORMALLY AN INCREASE OF FIVE TO 10 HORSEPOWER IS NOT UNHEARD OF, BUT SINCE OUR CAM IS SIGNIFICANTLY LARGER WE'RE GONNA SEE MORE. WE SET THE TIMING BACK TO 32 DEGREES. ALRIGHT LET HER RIP. OTHER THAN THAT EVERYTHING IS THE SAME. LIKE ANY PARTS CHANGE, WE'LL RUN THE ENGINE BEFORE WE MAKE ANY PULLS TO CHECK EVERYTHING OUT.

(MIKE)>> THAT THING SOUNDS AWESOME!

(PAT)>> IT'S A LITTLE CRACKLIER.

(MIKE)>> I COULD SIT AND LISTEN TO IT ALL DAY.

(PAT)>> I DON'T KNOW IF CRACKLIER IS A WORD,

BUT I JUST MADE THAT UP.

(MIKE)>> SOUNDS GOOD, THREE TO FIVE. [ engine revving ]

(MIKE)>> 603 ON POWER, 639 ON TORQUE AT 5,000. IT'S DOWN 20 ON HORSEPOWER AND DOWN 17 ON TORQUE.

(PAT)>> WHEN IT STARTS TO GET UP INTO THE RPM RANGE, WHEN THE THING STARTS HAVING A HIGHER AMOUNT OF VOLUMETRIC EFFICIENCY, THAT'S WHEN THE CAM WILL REALLY START TO COME IN.

(MIKE)>> SO WE'LL MAKE ANOTHER UP TO 6,000 RPM. WOW, 702, 645. PAT PULLS A PLUG, WHICH SHOWS WE'RE SAFE ENOUGH TO UP THE TIMING TO 34 DEGREES AND TAKE IT TO 6,500 RPM.

(PAT)>> 706 HORSEPOWER, 644 POUND FEET OF TORQUE, AND THAT'S AS FAR AS WE'LL PUSH THIS SETUP. TIME FOR AN INDUCTION CHANGE AND IT'S GONNA BE A BIG ONE.

A WEIAND HIGH RAM INTAKE TOPPED OFF WITH TWO QUICK FUEL TECHNOLOGIES BLACK DIAMOND 750'S. THIS SPECIAL OIL PUMP DRIVE WILL PLUG THE UNUSED DISTRIBUTOR HOLE.

(MIKE)>> WITH THE TIMING BACK AT 32 DEGREES WE'LL TAKE IT TO 6,500.

(PAT)>> THE CARB'S BUTTERFLIES ARE NOW LINE OF SIGHT WITH THE INTAKE VALVES AND THE LONGER RUNNERS WILL INCREASE THE TORQUE LOST FROM A BIGGER CAM INSTALL.

(MIKE)>> 737, 666, AND ONLY 32 DEGREES OF TIMING.

(PAT)>> IT'S SO SAFE.

(MIKE)>> LET'S MAKE A CARB CHANGE. THE LEFT SIDE RAN RICHER. SMALLER JETS WILL FIX IT. AND THE LAST PULL IS TO 6,800. I SAW THAT NEEDLE HIT A REALLY GOOD NUMBER.

(PAT)>> THAT'S PRETTY AWESOME RIGHT THERE, IT'S GONNA BE GOOD, IT'S GONNA BE GOOD!

(MIKE)>> WHOO 750, 680, THAT IS NASTY. WOW, WE COOLED IT DOWN A LITTLE MORE THAN NORMAL GOING FOR A BIG NUMBER AND WE NAILED IT.

(PAT)>> IN OUR OPINION THE TUNNEL RAM NOT ONLY LOOKS AWESOME, IT ACTUALLY IS THE BEST SETUP FOR THIS ENGINE COMBINATION CRANKING OUT BIG POWER NUMBERS EVERYWHERE IN THE RANGE.

(MIKE)>> NOW THIS ENGINE ISN'T GOING ANYWHERE. WE'RE BRINGING IT BACK IN THE NEAR FUTURE TO SHOW ITS FULL POTENTIAL.

THAT'S RIGHT, THIS BRACKET BLASTER IS GOING FULL RACE STATUS BECAUSE WE'RE TURNING IT INTO A HIGH COMPRESSION RACE BULLET. NOW THAT'LL INCLUDE NEW RODS, PISTONS, CYLINDER HEADS, INTAKE MANIFOLD, CARBS, AND THE CAM SHAFT.

YOU DON'T WANT TO MISS IT.

(PAT)>> BUT TODAY THAT'S IT FOR US, WE'LL SEE YOU NEXT TIME.

Show Full Transcript

(MIKE)>> IT'S A LITTLE DIFFERENT NOT HAVING ALL NEW PARTS, HUH?

(PAT)>> THIS IS GONNA BE A GOOD ONE THOUGH.

(MIKE)>> WELCOME TO ENGINE POWER. TODAY WE'RE BUILDING A BIG BLOCK CHEVY BRACKET BLASTER FROM BITS AND PIECES WE'VE HAD LAYING AROUND THE SHOP. NOW WE'RE LIKE A BIG PERCENTAGE OF YOU GUYS THAT HAVE PARTS FROM SEVERAL DIFFERENT ENGINES JUST FLOATING AROUND. ADD A COUPLE OF SPECIFIC ITEMS TO THOSE AND YOU CAN CREATE A SUPER RELIABLE BULLET TO POUND ON AROUND TOWN AND HAVE A REALLY, REALLY CONSISTENT BRACKET ENGINE ON THE WEEKENDS.

(PAT)>> HOW WILL IT ACCOMPLISH THOSE GOALS?

WELL NUMBER ONE IS CUBIC INCHES. THE BIGGER THE ENGINE, THE EASIER IT IS TO MAKE NATURALLY ASPIRATED HORSEPOWER BECAUSE ALL THOSE INCHES MAKE TORQUE AND TORQUE IS WHERE HORSEPOWER IS CALCULATED FROM. THIS PARTICULAR BLOCK HAS A 4.560 BORE AND THE CRANK HAS A 4.375 STROKE, WHICH EQUALS 572 CUBIC INCHES. AND THAT'S BIG BY PRETTY MUCH ANYONE'S STANDARDS. THIS IS A TALL DECK GM 572 SPORTSMAN ENGINE THAT'S BEEN SITTING ON THE SHELF NEXT TO A PILE OF GREASY PARTS FOR QUITE SOME TIME. NUMBER TWO WE'RE USING 93 OCTANE PUMP GAS RIGHT FROM THE LOCAL GAS STATION, WHICH SIMPLIFIES EVERYTHING SINCE WE CAN GET GAS FOR IT ANYWHERE.

AND NUMBER THREE WE HAVE TO HAVE ADEQUATE INDUCTION, WHICH WE HAVE COVERED.

(MIKE)>> THE HEART OF THE INDUCTION ARE CHEVY PERFORMANCE'S BOWTIE 572-R CYLINDER HEADS THAT RECEIVED SPECIAL MESSAGING FROM LIVERNOIS MOTORSPORTS. ON THE DYNO WE'RE GOING TO TEST A SINGLE PLANE HIGH RISE THAT ACCEPTS A SINGLE DOMINATOR AND A TUNNEL RAM THAT IS CAPPED OFF WITH DUAL 4150 CARBS. THE VALVETRAIN IS ALL SOLID ROLLER AND THE CAMSHAFT HAS A SPECIAL FEATURE THAT IS MOSTLY

RECOGNIZED IN THE RACING WORLD. NOW FOR ACCURATE CAM SHAFT TIMING AND EASE OF MAINTENANCE A JESEL BELT DRIVE WILL SIMPLIFY THE TASK OF CHANGING CAMS ON THE DYNO. COMPLIMENTING IT IS AN MSD CRANK TRIGGER. THE FOUNDATION FOR POWER AND RELIABILITY LIES IN THE PARTS WE ALL USE. NOW THIS CRANK IS A 4340 FORGED STEEL UNIT THAT'S DESIGNED TO RUN A ONE PIECE REAR MAIN SEAL AND IT'S INTERNALLY BALANCED. NOW THE JOURNALS HAVE A LARGE RADIUS FOR ADDITIONAL STRENGTH BUT THAT ALSO MEANS A NARROW BEARING MUST BE USED. THE RODS ARE MADE OF THE SAME MATERIAL AS THE CRANK SHAFT, 4340 FORGED STEEL. NOW THEY HAVE A SIX-535 CENTER TO CENTER AND ARE AN HBEAM DESIGN. ARP 2,000 BOLTS WILL KEEP THE CAPS IN PLACE.

(PAT)>> THE STARTING POINT FOR THIS PROJECT IS BLOCK PREP, AND THIS ONE NEEDS SOME TLC DUE TO THE AMOUNT OF RUN TIME IT HAS ON IT.

NOW WE'VE ALREADY MEASURED THE BORES, THE CRANK

JOURNALS, THE RODS AND PISTONS, AND THE DECKS, AND EVERYTHING LOOKS REALLY GOOD. SO THE DECISION WAS MADE TO FRESHEN IT UP WITH NEW RINGS AND BEARINGS, AND PUT IT TOGETHER WITH MOST OF THE PARTS FROM THE PILE.

THE TLC WE MENTIONED ARE ALL STEPS YOU CAN DO AT

HOME, LIKE REFINISHING THE CYLINDERS WITH A FLEX HONE

LIKE THIS ONE WE GOT FROM GOODSON. THE FIRST THING YOU WANT TO DO IS GRAB SOME WD 40 FOR LUBE AND SOME SHOP TOWELS BECAUSE IT

GETS A LITTLE MESSY. WITH THE FLEX HONE INSTALLED IN A VARIABLE FEED DRILL, HERE'S HOW IT'S DONE. SPRAY THE CYLINDER AND FLEX HONE WITH A FEW SHOTS OF WD. GET THE DRILL GOING RIGHT AS THE FLEX HONE GOES IN THE CYLINDER. CHECK YOUR PROGRESS OFTEN BECAUSE SOME BORES MIGHT

NEED MORE ATTENTION THAN OTHERS. I'M RUNNING THE DRILL WIDE OPEN AND CROSS HATCHING THE BORE RATHER QUICKLY. THE END RESULT WILL BE BETWEEN A 35 AND 45 DEGREE CROSS HATCH LIKE THIS. TINY AND SHALLOW VERTICAL SCRATCHES ARE STILL PRESENT BUT WON'T EFFECT HOW THE ENGINE PERFORMS. THE IMPORTANT PART IS THE BORES ARE SURFACE

RECONDITIONED FOR THE NEW RINGS. DON'T LET THE HONE STOP INSIDE THE BORE. KEEP IT MOVING UP AND DOWN AS WELL AS ROTATING ALL THE TIME. THE REASON WE CAN USE THIS CYLINDER FINISHING METHOD IS BECAUSE THE CYLINDERS WE HAVE ARE STRAIGHT, ROUND, AND THE PROPER SIZE. IF THE BORES WERE HEAVILY WORN IT WOULD NEED TO BE

BORED AND HONED AT A MACHINE SHOP. WHILE WE HAVE THE DRILL IN HAND WE'RE GONNA DO THE LIFTER BORES AS WELL, JUST WITH A SMALLER VERSION.

THE SAME TECHNIQUE IS USED AS THE CYLINDER BORES. JUST REMEMBER YOU'RE NOT TRYING TO CHANGE THE SIZE, JUST REFRESH THE SURFACE FINISH. ANOTHER PREP STEP IS DEBURRING THE BLOCK, WHICH

MEANS REMOVING ALL THE SHARP EDGES AND CASTING LINES. AND THAT HAS A COUPLE OF BENEFITS. THE FIRST BEING YOU HAVE A SAFER BLOCK TO WORK WITH SO YOU DON'T CUT YOURSELF. AND THE SECOND, IT HELPS PREVENT A PLACE FOR A CRACK TO START. A DIE GRINDER AND A CARBIDE BURR ARE THE TOOLS FOR THE JOB.

THESE ARE BOTH FROM MATCO. THE FOCUS IS ON SHARP EDGES AND RAISED CASTING LINES ALL OVER THE BLOCK. BECAUSE THIS ONE'S POWDER COATED, THEY'LL

BE EASY TO FIND.

DON'T USE MUCH PRESSURE, THE BURR DOESN'T LIKE IT. A LIGHT PASS OVER TAKES CARE OF BUSINESS. NOW ALL WE NEED TO DO IS REMOVE THE REST OF THE OIL GALLERY PLUGS. THIS WILL INSURE THE BLOCK GETS CLEANED INSIDE AND OUT IN THE JET WASHER. OUR KUNDAL SNAP TRACK HOIST WILL LOAD IT INTO THE JET WASHER WHERE IT WILL STAY FOR ONE HOUR. THE REST OF THE PARTS ALSO GET A CLEANING, STARTING WITH THE CRANK. IT WILL SIT FOR 15 MINUTES. THEN WE CAN GIVE THE PISTONS AND RODS

THE SAME TREATMENT.

(ANNOUNCER)>> WITH EVERYTHING CLEANED AND PREPPED, THE BUILD BEGINS, THAT'S NEXT!

(MIKE)>> WE'RE BACK AND THIS BUILD IS CONTINUING WITH ASSEMBLY. NOW WE ALREADY CHECK ALL OF OUR MAIN BEARING CLEARANCES AND WE HAVE BETWEEN 27 AND 32 TEN

THOUSANDTHS, WHICH GIVES US THE GREEN LIGHT TO CONTINUE. A UNIQUE FEATURE TO THIS BLOCK IS IT HAS GROOVES IN THE UPPER MAIN SADDLES. THAT ALLOWS EXTRA HOLES TO BE DRILLED IN THE BEARING

ITSELF FOR ADDITIONAL OILING, WHICH INCREASES BEARING LONGEVITY.

USING A POCKET SCALE GET THE LOCATION THE HOLE NEEDS TO BE DRILL IN. TRANSFER THAT TO THE BEARING, AND DRILL A HOLE WITH THE BEARING IN A SECURE SPOT. [ drill spinning ]

(MIKE)>> FINALLY WE'LL USE LARGER BITS TO DEBURR THE HOLE ON EACH SIDE, AND THIS LITTLE BIT OF

RACING TECH IS COMPLETE.

(PAT)>> THESE BEARINGS ARE NARROWED TO CLEAR THE RADIUS ON THE CRANK JOURNAL. WE ORDERED THEM FROM CLEVITE WITH THEIR ANTIFRICTION COATING. WITH A LITTLE ASSEMBLY LUBE ON EACH ONE, THE CRANK IS CAREFULLY LAID INTO THE BLOCK AND THE REAR MAIN SEAL IS POSITIONED. NOW LUBE THE LOWER BEARINGS AND POSITION THE

MAIN CAPS, TAP THEM DOWN, AND LIGHTLY SNUG THEM UP. USING A DEAD BLOW, TAP THE CRANK FROM FRONT TO REAR AND REAR TO FRONT TO SQUARE UP THE THRUST BEARING. NOW TORQUE THE MAINS TO 95 FOOT POUNDS USING EXTREME PRESSURE LUBE, AND THE CRANK IS SECURED.

(MIKE)>> THE NEXT THING TO GO IN THE ENGINE ARE OUR PISTON AND ROD ASSEMBLIES. NOW WE ALREADY FILE FIT OUR MAHLE RING SET. THEY SENT US A SIXTEENTH, SIXTEENTH, THREESIXTEENTH PACKAGE THAT USES A LOW TENSION OIL RING, WHICH WILL FREE UP A LITTLE HORSEPOWER.

NOW WE GAPPED THE TOP RING AT 22 THOUSANDTHS, AND THE SECOND RING AT 24. USING MOTOR OIL, LUBE THE RINGS AND SKIRTS OF THE PISTON, AND DROP THE ASSEMBLY INTO A RING COMPRESSOR.

THE ROD BEARINGS ARE NARROWED AS WELL DUE TO THE RADIUS ON THE JOURNAL. HIGH VISCOSITY ASSEMBLY LUBE WILL PROTECT THEM DURING THE INITIAL FIRE UP. NOW ALIGN THE SETUP WITH THE CYLINDER BORE, AND TAP THEM IN WITH A DEAD BLOW PISTON KNOCKER LIKE THIS. (PAT>> UNDERNEATH, YOU READY?

(MIKE)>> YEP, COME ON.

(PAT)>> BE CAREFUL NOT TO NICK THE JOURNAL AS YOU GUIDE THE BIG END OF THE ROD DOWN TO IT. NOW THE CAP AND ARP 2,000 BOLTS GO IN AND GET SNUGGED DOWN. FINAL TORQUING HAPPENS AFTER THEY'RE ALL IN. FORGED ALUMINUM PISTONS FROM JE FILL THE BORES. THEY'RE A FLAT TOP DESIGN WITH A SINGLE VALVE RELIEF, WHICH MEASURES THREE CC'S DEEP. THIS IS PERFECT FOR OUR PUMP GAS FRIENDLY SETUP SINCE OUR COMPRESSION RATIO CALCULATES TO NINE

POINT SEVEN TO ONE.

(MIKE)>> NOW WE CAN TORQUE THE ROD BOLTS TO 75 POUND FEET.

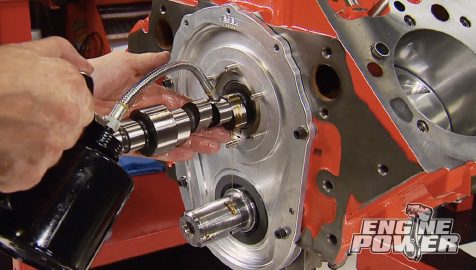

(PAT)>> THE CAM SHAFT IS NEXT. IT'S FROM THE USED PILE. IT'S A MECHANICAL ROLLER. DURATION AT 50 IS 260 ON THE INTAKE, 270 ON THE EXHAUST WITH 110 DEGREES OF LOBE SEPARATION. LIFT IS 670 ON BOTH SIDES. BOLTING TO IT IS THE DRIVE HUB ADAPTER JESEL SENT SO WE CAN RUN THEIR BELT DRIVE. ON THE FRONT OF THE ENGINE JESEL'S FRONT COVER GOES ON FIRST.

YOU MAY NEED TO CLEARANCE THE BLOCK, OURS WAS ALREADY DONE. THIS CAM HAS A STANDARD FIRING ORDER AND WILL BE SWAPPED OUT FOR A SPECIAL CAM BACK ON THE DYNO AFTER WE SEE WHAT KIND OF POWER THIS ONE MAKES. WITH A SHIM IN PLACE, WE CAN INSTALL THE THRUST

PLATE, WHICH HAS A THIN LAYER OF SILICONE TO PREVENT AN OIL LEAK. THE SEAL STAYS DRY SINCE IT'S TEFLON. WITH IT SNUG WE CAN CHECK THE CAM SHAFT'S END PLAY. JESEL SPECIFIES BETWEEN EIGHT AND 12 THOUSANDTHS. WE ARE IN. [ hammer tapping ]

(PAT)>> THE TIMING MARKS ARE ALIGNED FOR THE CRANK AND CAM, WHICH GETS US READY TO INSTALL THE BELT. IT'S A ROUND TOOTH COG STYLE AND GOES IN WITH THE UPPER PULLEY ASSEMBLY ALL AT ONCE. THAT COMPLETES THE LINK BETWEEN THE CAM AND THE CRANK. THE LAST THING TO DO IS DEGREE THE CAM. UNDERNEATH THE HIGH VOLUME OIL PUMP GOES ON. IT HAS THE PICK UP ATTACHED FOR THE PAN WE'LL USE. SECURING IT IS A SPECIAL STUD THAT WORKS IN

CONJUNCTION WITH THE WINDAGE TRAY. IT GETS POSITIONED ON THE STAND OFFS FROM A FEW OF THE MAIN FASTENERS. ITS JOB IS TO DISRUPT THE VORTEX OF OIL IN THE CRANK

CASE CAUSED BY CRANKSHAFT ROTATION. WITH OUR FEL PRO GASKET IN PLACE, THE EIGHT QUART MOROSO DRAG RACE PAN GOES ON, AND WITH THAT THE SHORT BLOCK IS COMPLETE. REMEMBER WHEN WE SAID WE HAD THE INDUCTION PART COVERED, WELL THIS IS WHAT WE WERE TALKING ABOUT. THIS IS A CHEVY PERFORMANCE CASTING THAT FOUND ITS WAY TO LIVERNOIS MOTORSPORTS, WHERE IT

RECEIVED SOME OF THEIR PORTING MAGIC ON THEIR CNC EQUIPMENT.

LAST TIME THESE WERE ON A BIG INCH BIG BLOCK THEY PRODUCED SIGNIFICANT POWER GAINS. SO WE'RE GONNA SEE WHAT THEY'RE GONNA DO FOR US. THESE SPRINGS AND ALL THE COMPONENTS CAME FROM CRANE CAMS. SO WE SET THE INSTALL HEIGHT AT TWO-100 AND WE'RE READY TO ASSEMBLE THEM. THE SHIM AND LOCATOR ARE FIRST, FOLLOWED BY THE SEAL, WHICH CAN BE A LITTLE TRICKY INSTALLING,

SO BE CAREFUL. NEXT LUBE THE VALVE STEM AND SLIDE IT INTO THE GUIDE IN A ROTATING FASHION SO THE ENTIRE GUIDE IS SLICKED UP. THE DUAL SPRING AND TITANIUM RETAINER IS NEXT, AND IT ALL GETS COMPRESSED WITH OUR MTI SPRING COMPRESSOR FROM GOODSON. NOW PLACE THE LOCKS ON THE STEM AND RELEASE THE COMPRESSOR. THAT'S IT, JUST 15 MORE TO GO. WITH CRANE'S ULTRA PRO LIFTERS INSTALLED IN A 30 THOUSANDTHS THICK COMEDIC HEAD GASKET IN PLACE, THE HEADS GET MATED TO THE BLOCK. WE'LL NEED THE CYLINDER HEAD INSTALLER.

THERE YOU GO. WE'RE TORQUEING THE HEADS TO 75 POUND FEET AND DECLARING LONG BLOCK STATUS.

(ANNOUNCER)>> COMING UP ITS MAKE OR BREAK ON THE DYNO.

(MIKE)>> WE'RE BACK AND OUR 572 CUBIC INCH BRACKET BLASTER IS STRAPPED TO THE DYNO. NOW WE STILL HAVE A FEW THINGS TO DO AND IT'S GONNA HAPPEN FAST. SO MAKE SURE YOU PAY ATTENTION.

STRAPPED TO THE TOP OF THE HEADS ARE COMP CAM'S ONE POINT SEVEN RATIO SHAFT MOUNTED ROCKERS, AND CONTROLLING THEM ARE THE THREEEIGHTHS PUSH RODS. CAST ALUMINUM VALVE COVERS WILL COVER THEM UP. AND FOR INCREASED RING SEAL AND LESS INTAKE CHARGE CONTAMINATION A MISTER GASKET CRANK CASE EVAC KIT HAS BEEN INSTALLED. AND FOR INDUCTION A CHEVY PERFORMANCE HIGH RISE TOPPED OFF WITH A HOLLEY 1,150 CFM DOMINATOR. AN MSD CRANK TRIGGER BOLTS TO THE BALANCER, THE

BRACKET AND PICK UP ARE INSTALLED, AND THE GAP IS SET. WRAPPING UP THE RACY PARTS IS A JESEL FRONT DISTRIBUTOR DRIVE, CAP, AND EXCEL EXTREME 9,000 PORCELAIN BOOTED WIRES. AN ELECTRIC WATER PUMP WILL CIRCULATE THE COOLING JUICE.

AND THE LAST LINK IS THE EXHAUST, TWO INCH HOOKER SUPER COMPS THAT FLOW INTO THREE AND A HALF INCH PIPE TO DIRECT THE EXHAUST GASES OUT OF THE ENGINE.

WITH 93 OCTANE SHELL PUMP GAS FILLING THE CELL AND ALL THE FLUIDS PRIMED, HERE'S THE INITIAL FIRE UP. [ engine starts and revs ]

(MIKE)>> THAT SOUNDS LIKE BIG BLOCK POWER RIGHT THERE. PAT IS CONFIRMING THE TIMING IS AT 32 DEGREES. SINCE THE JESEL DISTRIBUTOR DRIVE IS UP FRONT, WE PUT AN MSD DISTRIBUTOR IN TO DRIVE THE OIL PUMP AND COMPLETE THE OIL CIRCUIT OUT BACK. WITH A BREAK IN AND WARM UP CYCLE BEHIND US.

(PAT)>> BIG BLOCK CHEVY TAKE ONE.

(MIKE)>> HERE'S WHAT A 572 INCH RAT WITH NINE POINT SEVEN TO ONE COMPRESSION AND 93 OCTANE DOES ON THE PUMP FROM 3,000 TO 5,000 RPM. LOADED UP GOOD, NICE AND CLEAN. THE PAINT'S STILL BURNING OFF THE HEADERS A LITTLE BIT. 623 ON POWER.

(PAT)>> THAT AIN'T BAD.

(MIKE)>> AND CLIMBING LIKE A MONSTER, 656 FOOT POUNDS. YOU WANT TO STEP UP RPM?

(PAT)>> YEAH LET'S STEP UP RPM.

(MIKE)>> THREE TO 65, ACTIVATED, HERE WE GO. [ engine revving ]

(PAT)>> THAT LOOKED PRETTY DECENT.

(MIKE)>> GOSH IT SOUNDS SO GOOD.

(PAT)>> THAT LOOKED PRETTY DECENT RIGHT THERE. THAT'S PRETTY NICE!

(MIKE)>> 672 HORSE, 657 POUND FEET. WELL LET'S SEE HERE. WE'VE GOT TWO OTHER SCENARIOS WE'VE GOT TO DO.

THE CAM SHAFT WITH THE FOURSEVEN SWAP AND THE TUNNEL RAM WITH TWO FOURS. SO LET'S GO AHEAD AND JUST PUT 36 DEGREES IN IT, SEE WHAT IT DOES WITH THIS SETUP, AND CALL IT A GAME AND DO THE CAM SWAP.

(PAT)>> I'M ALL OVER THAT.

(MIKE)>> MAN, SHE FIRES UP EASY. SAME SWEEP, THREE TO 65. 674, 660.

(PAT)>> SOUNDS MEAN!

(MIKE)>> I SAY WE CHANGE THE STICK, RUN IT ONCE WITH THIS INTAKE, THEN DO THE TUNNEL RAM AND LET THESE FOLKS SEE WHAT THE TUNNEL RAM IS CAPABLE OF.

(PAT)>> WE'RE GONNA FIND OUT.

(MIKE)>> COOL!

(PAT)>> WE CONCLUDED THE STANDARD CAM RUNS AND GOT 674 HORSEPOWER AND 660 POUND FEET OF TORQUE. BUT LIKE ALL THINGS THERE IS ROOM FOR IMPROVEMENT. THIS NEW BUMP STICK IS 14 DEGREES LARGER EVERYWHERE AND IS ON 114 DEGREES OF LOBE SEPARATION.

LIFT IS 100 THOUSANDTHS MORE AT THE VALVE. PLUS IT HAS A FOURSEVEN FIRING ORDER SWAP BUILT IN. WHAT WE MEAN BY A FOURSEVEN SWAP IS WE'VE CHANGED THE FIRING ORDER OF THE CAM, AND THAT DOES A COUPLE OF DIFFERENT THINGS. ONE, IT REDUCES TORSION ON THE CRANK SHAFT AND THAT HELPS REDUCE MAIN BEARING LOADING BUT JUST AS IMPORTANT IT CHANGES THE PULSES BACK INTO THE INTAKE MANIFOLD AND THAT HELPS EVEN OUT FUEL DISTRIBUTION. NORMALLY AN INCREASE OF FIVE TO 10 HORSEPOWER IS NOT UNHEARD OF, BUT SINCE OUR CAM IS SIGNIFICANTLY LARGER WE'RE GONNA SEE MORE. WE SET THE TIMING BACK TO 32 DEGREES. ALRIGHT LET HER RIP. OTHER THAN THAT EVERYTHING IS THE SAME. LIKE ANY PARTS CHANGE, WE'LL RUN THE ENGINE BEFORE WE MAKE ANY PULLS TO CHECK EVERYTHING OUT.

(MIKE)>> THAT THING SOUNDS AWESOME!

(PAT)>> IT'S A LITTLE CRACKLIER.

(MIKE)>> I COULD SIT AND LISTEN TO IT ALL DAY.

(PAT)>> I DON'T KNOW IF CRACKLIER IS A WORD,

BUT I JUST MADE THAT UP.

(MIKE)>> SOUNDS GOOD, THREE TO FIVE. [ engine revving ]

(MIKE)>> 603 ON POWER, 639 ON TORQUE AT 5,000. IT'S DOWN 20 ON HORSEPOWER AND DOWN 17 ON TORQUE.

(PAT)>> WHEN IT STARTS TO GET UP INTO THE RPM RANGE, WHEN THE THING STARTS HAVING A HIGHER AMOUNT OF VOLUMETRIC EFFICIENCY, THAT'S WHEN THE CAM WILL REALLY START TO COME IN.

(MIKE)>> SO WE'LL MAKE ANOTHER UP TO 6,000 RPM. WOW, 702, 645. PAT PULLS A PLUG, WHICH SHOWS WE'RE SAFE ENOUGH TO UP THE TIMING TO 34 DEGREES AND TAKE IT TO 6,500 RPM.

(PAT)>> 706 HORSEPOWER, 644 POUND FEET OF TORQUE, AND THAT'S AS FAR AS WE'LL PUSH THIS SETUP. TIME FOR AN INDUCTION CHANGE AND IT'S GONNA BE A BIG ONE.

A WEIAND HIGH RAM INTAKE TOPPED OFF WITH TWO QUICK FUEL TECHNOLOGIES BLACK DIAMOND 750'S. THIS SPECIAL OIL PUMP DRIVE WILL PLUG THE UNUSED DISTRIBUTOR HOLE.

(MIKE)>> WITH THE TIMING BACK AT 32 DEGREES WE'LL TAKE IT TO 6,500.

(PAT)>> THE CARB'S BUTTERFLIES ARE NOW LINE OF SIGHT WITH THE INTAKE VALVES AND THE LONGER RUNNERS WILL INCREASE THE TORQUE LOST FROM A BIGGER CAM INSTALL.

(MIKE)>> 737, 666, AND ONLY 32 DEGREES OF TIMING.

(PAT)>> IT'S SO SAFE.

(MIKE)>> LET'S MAKE A CARB CHANGE. THE LEFT SIDE RAN RICHER. SMALLER JETS WILL FIX IT. AND THE LAST PULL IS TO 6,800. I SAW THAT NEEDLE HIT A REALLY GOOD NUMBER.

(PAT)>> THAT'S PRETTY AWESOME RIGHT THERE, IT'S GONNA BE GOOD, IT'S GONNA BE GOOD!

(MIKE)>> WHOO 750, 680, THAT IS NASTY. WOW, WE COOLED IT DOWN A LITTLE MORE THAN NORMAL GOING FOR A BIG NUMBER AND WE NAILED IT.

(PAT)>> IN OUR OPINION THE TUNNEL RAM NOT ONLY LOOKS AWESOME, IT ACTUALLY IS THE BEST SETUP FOR THIS ENGINE COMBINATION CRANKING OUT BIG POWER NUMBERS EVERYWHERE IN THE RANGE.

(MIKE)>> NOW THIS ENGINE ISN'T GOING ANYWHERE. WE'RE BRINGING IT BACK IN THE NEAR FUTURE TO SHOW ITS FULL POTENTIAL.

THAT'S RIGHT, THIS BRACKET BLASTER IS GOING FULL RACE STATUS BECAUSE WE'RE TURNING IT INTO A HIGH COMPRESSION RACE BULLET. NOW THAT'LL INCLUDE NEW RODS, PISTONS, CYLINDER HEADS, INTAKE MANIFOLD, CARBS, AND THE CAM SHAFT.

YOU DON'T WANT TO MISS IT.

(PAT)>> BUT TODAY THAT'S IT FOR US, WE'LL SEE YOU NEXT TIME.