Ford vs Chevy: Small Displacement Showdown

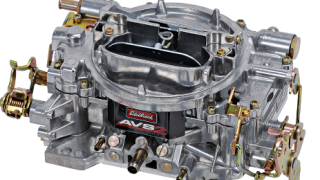

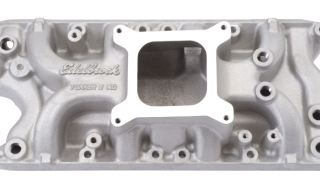

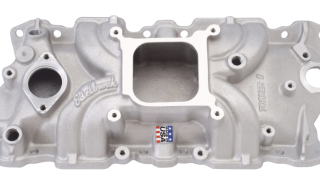

The TIMELESS Debate is on. Ford vs. Chevy. We start with a stock 305 Chevy and a 302 Ford. After an initial baseline, we see how they stack up against each other with the same mild upgrades. We find out, dollar for horsepower, who comes out on top.

Season 11

Episode 9