Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Holley

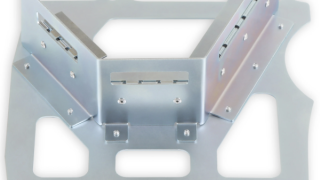

Holley Godzilla High-Mount Accessory Drive - With Holley Swap Oil Pan & Pump - Base Kit

Apocalypse Performance

2020+ Ford 7.3L Godzilla Billet Fuel Rails

Apocalypse Performance

725cc Ev14 HIgh Impedance Fuel Injectors

Apocalypse Performance

Stainless Works 20-21 Ford F-250/F-350 7.3L Headers