Super Street 427ci SBC Part 2

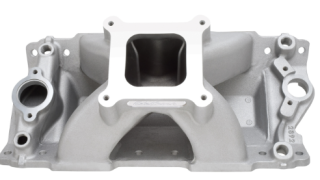

We continue with our aftermarket pump gas 427ci Small Block Chevy engine, with plans on getting it into the Dyno Cell. It’s getting finished off with a high flowing, off the shelf induction and rock solid valvetrain before we run some 93-octane fuel thru it and see what it puts out on the Dyno.

Season 11

Episode 16