More '01 Mazda B2500/Ford Ranger "Rolling Thunder" Episodes

More Rolling Thunder Episodes

Trucks! Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

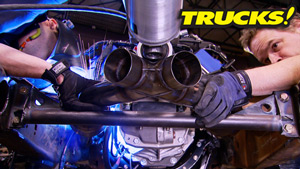

Denny's Driveshaft

Custom 1350 3" Aluminum Driveshaft"

Factory Five Racing,Inc.

Tubular Front Lower Control Arms

JD Squared Inc.

Model 32 tubing bender with upgraded hydraulic attachment and Notch Master tubing notcher.

Maximum Motorsports

Solid Rack and Pinion Mounting Bushings

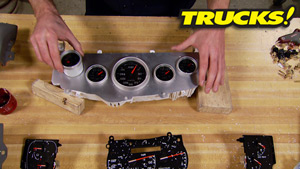

Tremec

Tremec T56 MAGNUM 6-speed