More '01 Mazda B2500/Ford Ranger "Rolling Thunder" Episodes

More Rolling Thunder Episodes

Trucks! Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Dupli-Color

Paint, Engine, Enamel with Ceramic Resin, Semi-Gloss, Black, 12 oz., Aerosol, Each

Edelbrock

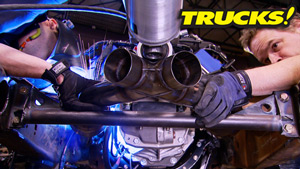

Supercharger System, E-Force, Serpentine, Black Powdercoated, Intercooler, Chevrolet/GMC, 4.8L/5.3L, Kit

APR Performance

Carbon Fiber NACA Duct Type 1, Universal, each

Bondo

Bondo, Fiberglass Resin, Liquid, 1 gal.

Clausen

Clausen ZGF-2 Z-GLAS Fiberglass Reinforced Filler w/ Red Cream Hardener

Matco Tools

4-in-1 Tube Bender