How An Engine Dyno Works

With Engine Power’s new dyno cell, Cell Block D, successfully installed it’s time for Bret Williamson from SuperFlow to update the actual dynamometer. But before we dive into the upgrades, let’s run over how an engine dyno works.

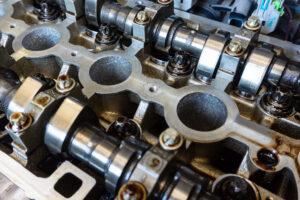

The twisting an engine makes is called torque. To measure it accurately, the dynamometer acts like a giant water break. The engine’s crankshaft gets connected to the dyno’s impeller housing and water inside the housing creates resistance making it hard to turn the crankshaft. This heats up the water and puts a serious load on the impeller housing as it literally tries to rotate off the dyno’s frame. A force transducer bolted between the housing and the frame measures the rotational strain which the computer translates into torque and horsepower measurements. The hot water gets pumped back to the main storage tank for re-use. While most of the dyno’s water is used to absorb torque, some of it regulates engine temperature which makes for an accurate, efficient, and consistent dyno test system.

The Powermark absorber is a twin-rotor design that also uses an inlet and outlet valve. The advantage is that if you’re testing over a wide range of RPM, it lets you adjust for that so you can run the engine at whatever you want. SuperFlow’s Powermark Dynamometer can monitor a whopping 139 channels of engine data. And while the Engine Power doesn’t need that much, Bret did set the guys up to measure boost level. On the console side of the setup, the software is updated.

Before the dyno’s first use it needs calibration. Four hundred pounds of weights were hung to check the accuracy and the software was calibrated. Calibration is a matter of faith. If calibrating frequently is something you prefer, otherwise you can leave it alone until the day you think the numbers are wrong and then add the weights and check.